Abrasive Removal Systems

Improves work environment, productivity and machine system lifetime

We recommend that all WJS customers include an abrasive removal system in their machine solution. It is a valuable investment even if you cut just a few hours a week. Keeping the water tank clean from abrasive sludge gives huge benefits for the overall work environment and you avoid problems with a clogged tank in the future.

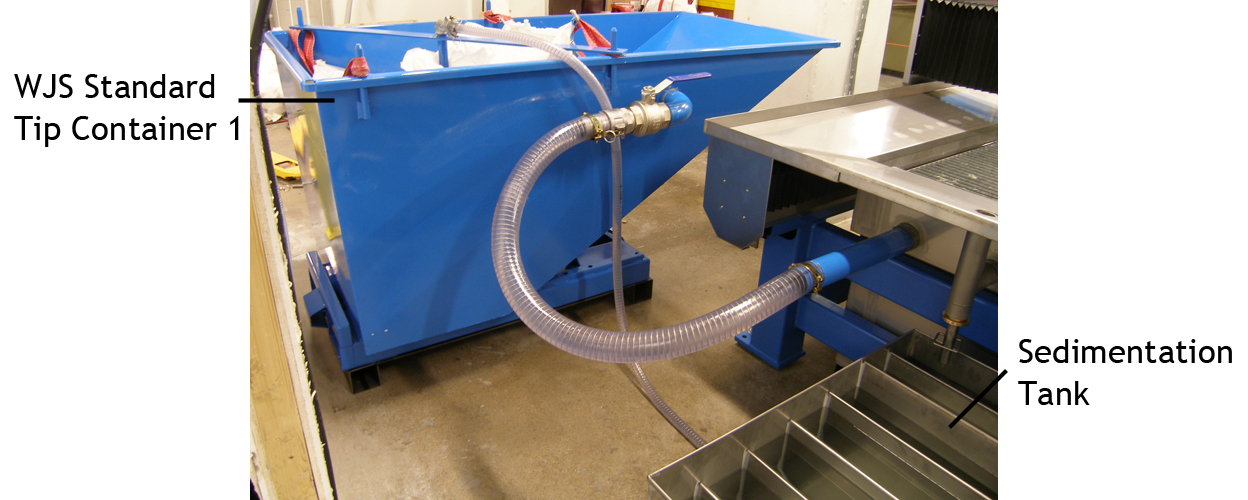

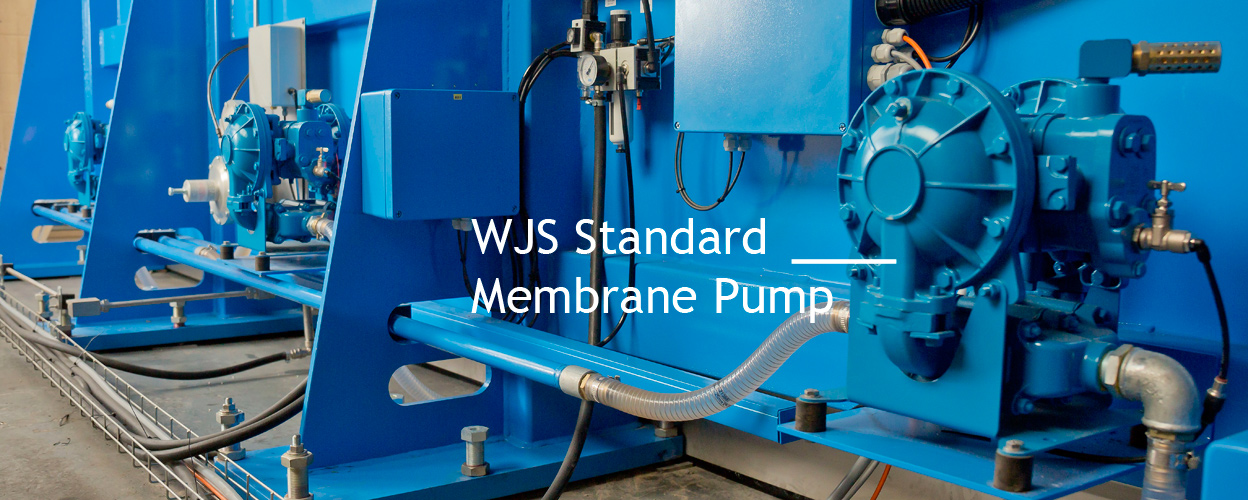

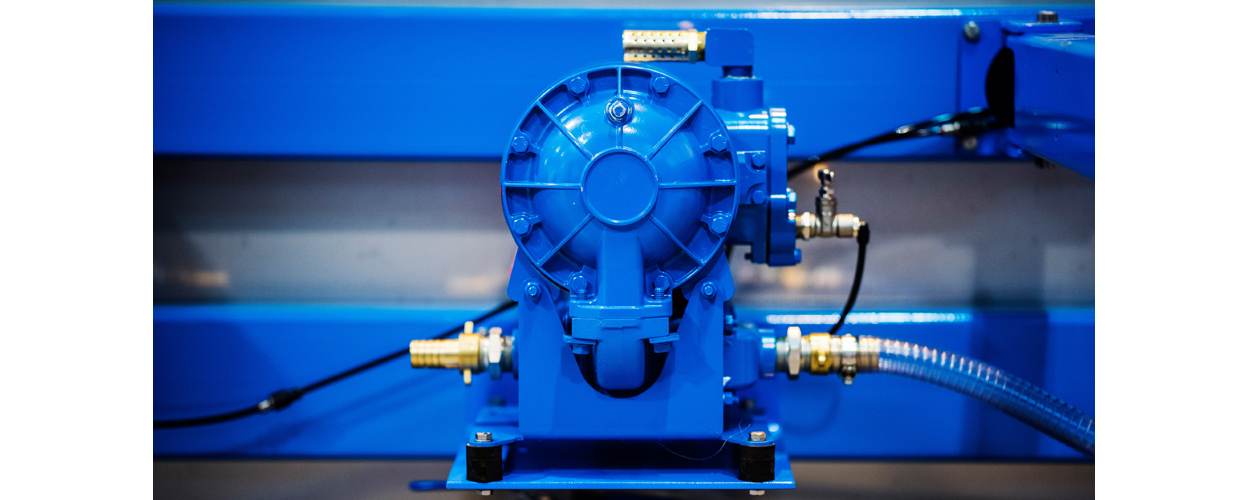

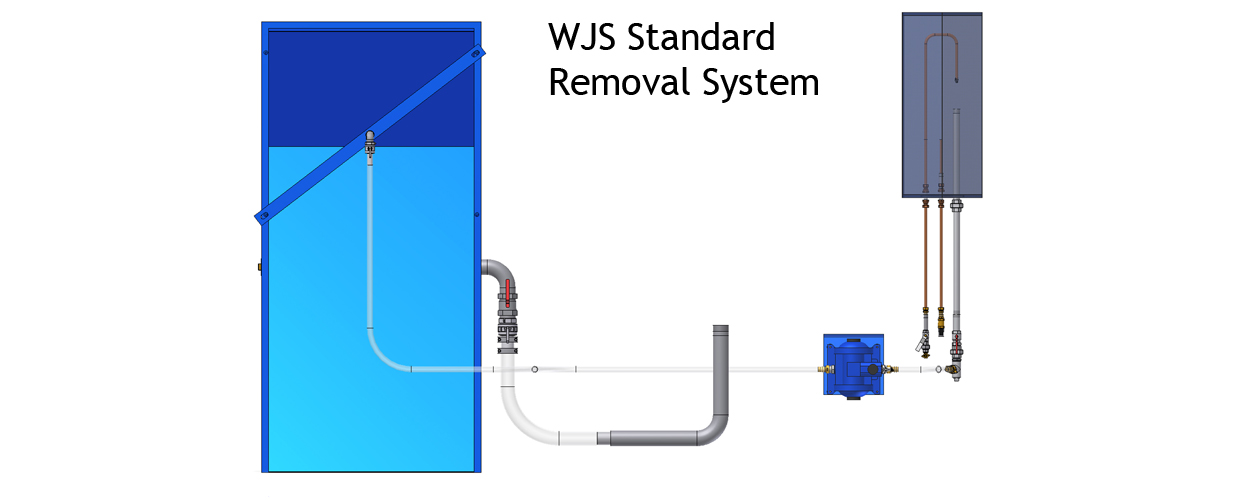

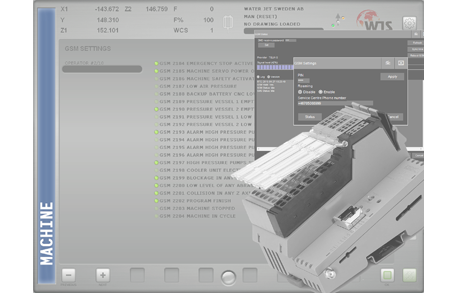

WJS Standard Removal System – Mounted in the bottom of the tank are suction units and the abrasive sludge is extracted by pressurized air diaphragm pumps. The sludge is pumped into a nylon bag in a tip container. While the abrasive is settling in the bag the excess water is led back into the cutting tank. The whole process is managed from the operator HMI.

Sludge Separation Tower – The Sludge Separation Tower separates the return water from the abrasive sludge. It enables dry big bag handling, simplifies the big bag removal and gives more efficient floor space usage. It can replace the tip container in WJS Standard Removal System.

ASAS Single/Double Removal System – smooth abrasive sludge handling for the biggest machines and largest volumes of abrasive consumption. The abrasive sludge is pumped straight into one of two large bags; the second bag is used as overflow for additional sedimentation. The use of the special bags ensures an excellent and reliable filtration process.

Sedimentation Tank – Waste water sedimentation cascade manufactured in stainless steel to clean the cutting water from larger particles before entering drain.

Contact

Five year performance warranty

We guarantee that all our machines keep the same tolerance level after five years as when the machine was first delivered.

Lifetime support by waterjet specialists

Our service team is highly specialized within the field of water jet cutting. Via our hotline support, our technical expertise is available on a 24/7 basis.

Klas Wallström

CMO

Sweden

Welcome

If you have questions, please call us at +46 457 455 440 or fill in the contact form and we will get in touch.