Mission Completed! A full-size 3D waterjet to Radius Aerospace.

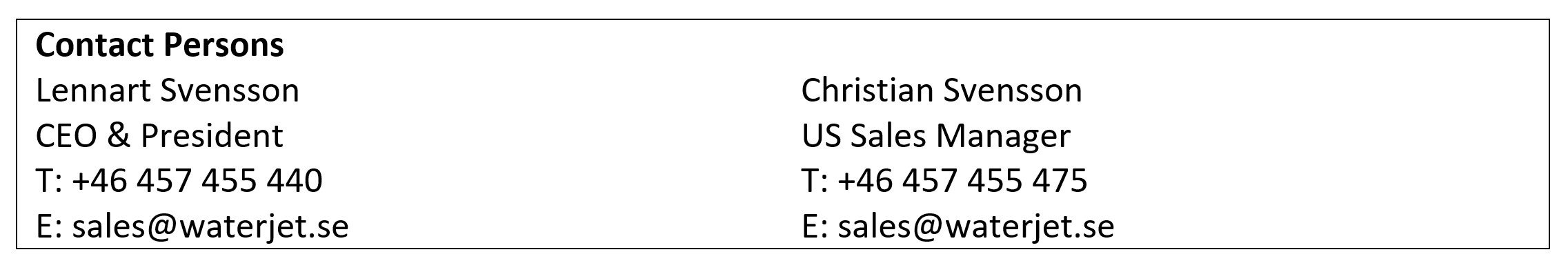

Elizabeth Robison, project manager at Radius Aerospace, defied the snowy winter and traveled from Hot Springs, Arkansas USA, to Ronneby, Sweden with one mission – to supervise the Factory Acceptance Test. “All our machine orders are based on specific customer requirements and testing before delivery is key to secure customer satisfaction”, tells Christian Svensson, US Sales Manager at Water Jet Sweden.

Radius Aerospace fabricates and manufactures a broad portfolio of aircraft and aerospace structures, components, sub-assemblies, and systems. The company focus on core services like forming, welding, bonding, machining, processing, and assembly.

Radius Aerospace has for many years used waterjet technology in their facility and have good experience of it, continuously improving their production processes. The company investigated new application areas for waterjet cutting and contacted Water Jet Sweden in the beginning of 2022. A dialogue started on how to optimize a machine design to best support their ideas, based on the FiveX – a unique 3D waterjet cutting system from Water Jet Sweden.

– Since both parties have complementary area of expertise, the specification of a machine like this is always a joint effort, tells Christian Svensson, US Sales Manager at Water Jet Sweden.

When it comes to a FiveX machine both size, features and fixtures are bespoken to fit the customers application and area of usage. Before the summer there was an agreement in how to design the setup and the machine order could be placed. In December the new machine was ready for delivery and it was time for a thorough two-day FAT (Factory Acceptance Test).

– It is key for us to meet customers’ expectations. There should be no problems or questions left when the machine leaves our production hall, says Christian Svensson. Securing machine performance before delivery is standard procedure for us.

The FAT was successful and, in the beginning of 2023, the new machine will be installed at Radius Aerospace facility in Arkansas, USA.

– On Radius Aerospace website you can read “We are dedicated and focused on providing the very highest quality fabrications with the best customer service while delivering the highest value”. We believe the new machine can be useful for Radius Aerospace to reach their ambition”, summarize Christian Svensson.

Photo 1: Approved! Standing on the machine: Radius Aerospace team, with Project leader Elizabeth Robinson. Water Jet Sweden team on the floor with US Sales Manager Christian Svensson in the middle.

Photo 2: The ± 0-120˚ cutting tool controlled with a joystick and a touch screen operator panel.

Photo 3: Production Manager Pär Rosenquist (left) managing the test process.

About Radius Aerospace

Radius Aerospace fabricates and manufactures a broad portfolio of aircraft and aerospace structures, components, sub-assemblies, and systems. The company focus on core services like forming, welding, bonding, machining, processing, and assembly. The company has production facilities in both USA and UK.

About Water Jet Sweden

Water Jet Sweden develops, manufactures and markets advanced solutions for water jet cutting and provides a quality aftermarket offer with service and parts. Since 1993 they strive to be the obvious first choice for customers worldwide who seek solutions in water jet cutting of high quality and high technical content. Today Water Jet Sweden has customers in more the 40 countries around the world.