Improve profitability with smart pump selection! Here is this year's news!

There are various reasons for investing in a new high-pressure pump, the heart of your machine system. A newer pump not only improve your up-time and lowers repair costs. Some models help you save energy. Or you can increase productivity with more horsepower or with higher pressure. No matter what you want to achieve, we can help you with pumps for all kinds of needs from the world’s leading pump manufacturers. Here we present latest news from KMT and BFT!

News 1: The 6000-bar pump from the BFT

BFT HYPERTRON® means that BFT takes a step into the 6000-bar technology. The pump is specially designed to increase productivity and is, like the SERVOTRON® model, based on short-stroke technology.

“With HYPERTRON®, you can achieve 30 to 50% higher cutting speed and cost efficiency thanks to high-pressure technology up to 6000 bar. It doesn’t matter if you want to work with two cutting heads or just with one cutting head, the HYPERTRON® provides the right pressure – from 500 to 6,000 bar. Flexibility and high performance in one and the same product”, as BFT describes it.

We have tested the BFT HYPERTRON® in our demo hall the last year with good results. If you cut large details and thick materials, 6000 bar can be a good choice.

Contact us for prices and more information. service@waterjet.se

With BFT HYPERTRON® BFT takes a step into 6000 bar technology. The pump is specially designed to increase productivity and is, like the SERVOTRON model, based on short-stroke technology. “With HYPERTRON®, you can achieve a 30 to 50% higher cutting speed and energy efficiency thanks to high-pressure technology up to 6000 bar. Whether you want to work with two cutting heads or just one cutting head, the HYPERTRON® ensures the right pressure – from 500 to 6,000 bar. Flexibility and high performance in one and the same product,” is how BFT describes it. We tested the BFT HYPERTRON® ourselves last year in our demo hall with good results and are now releasing it for sale. If you are cutting large details and thick materials, 6000 bar can be a good choice.

Other models from BFT

BFT ECOTRON®

BFT ECOTRON® is BFT’s base model that many people buy as an entry-level pump. The ECOTRON series is built with proven technology, high quality and offers a favorable price-performance ratio. The pump series has several different power classes and water flows. With a working pressure of 3500-4000 bar, it offers a good combination of long maintenance intervals and efficient cutting. ECOTRON is suitable for companies with regular daily operations and ordinary machine systems.

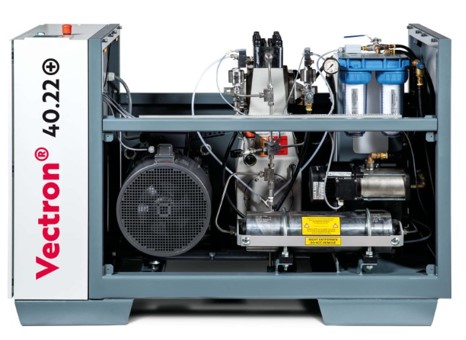

BFT VECTRON®

BFT VECTRON® is designed as an energy-efficient alternative to the ECOTRON® for simpler applications. Equipped with a direct-drive pump, the VECTRON® is about 25% more energy-efficient than models with the intensifier technology. The VECTRON® has a power supply of 22kW with a water flow of up to 3.5 l/min and a maximum working pressure of 3500 bar.

BFT SERVOTRON®

BFT SERVOTRON® offers a unique combination of performance and energy efficiency. The SERVOTRON® is powered by a servo motor instead of a traditional electric motor. This gives the pump a very energy-efficient operation, as it maintains full pressure even when the pump is stationary. The SERVOTRON® is available in power classes of 37 kW and 45 kW with a working pressure of 4000 bar. It is suitable for all levels of machine systems and is prepared from the outset for pump networks up to three pumps.

Contact us for prices and more information. service@waterjet.se

News 2: Entry-level model from KMT!

The KMT ARA is an affordable entry-level product that offers great value for money, with the ability to deliver up to 3800 bar. Developed to be robust and easy to handle, ARA is equipped with a proven intensifier concept for improved uptime and performance. ARA has a Siemens control system for high reliability and allows for easy reading of operator information and troubleshooting. ARA requires minimal floor space and has easy access to all components.

“Our engineers have transplanted the extremely successful concept of “SSEC” with pressure boosters into the ARA high-pressure system. This is not only characterized by its reliability. It is also at the forefront when it comes to easy maintenance,” KMT explains.

Contact us for prices and more information

Other models from KMT

KMT STREAMLINE SL-VI STD

STREAMLINE SL-VI STD is the first level of the KMT Streamline series. The STD models are suitable for applications with a need for pumping capacities up to 3800 bars, both pure water cutting and abrasive water cutting. A lower price option than the PLUS pump, but builds on the same advanced pump technology and can be used as a stand-alone unit or in pump networks. The model is available with several configuration options.

KMT STREAMLINE SL-VI PLUS

STREAMLINE SL-VI PLUS is a system for high cutting efficiency with a pump capacity of 4100 bar. The model uses the latest technology and very smart design for ease of use, reliability and convenience, making a system that provide high efficiency and profitability. The STREAMLINE SL-VI PLUS is available in a range of different horsepower sizes and configurations.

KMT STREAMLINE SL-VI PRO

The introduction of 6,200 bar with KMT PRO technology means that KMT took waterjet cutting to a new level. STREAMLINE SL-VI PRO today offers the most powerful combination of horsepower and thrust. The PRO series’ high pressure provides faster cutting, straighter incisions, finer cutting surface and less abrasive consumption. But extra high pressure also places higher demands on the component lifetime. With unique, patented design, KMT provides a 500-hour warranty on the high-pressure gaskets.

Contact us for prices and more information

CONTACT

Phone: + 46 457 455 445

E-mail: service@waterjet.se