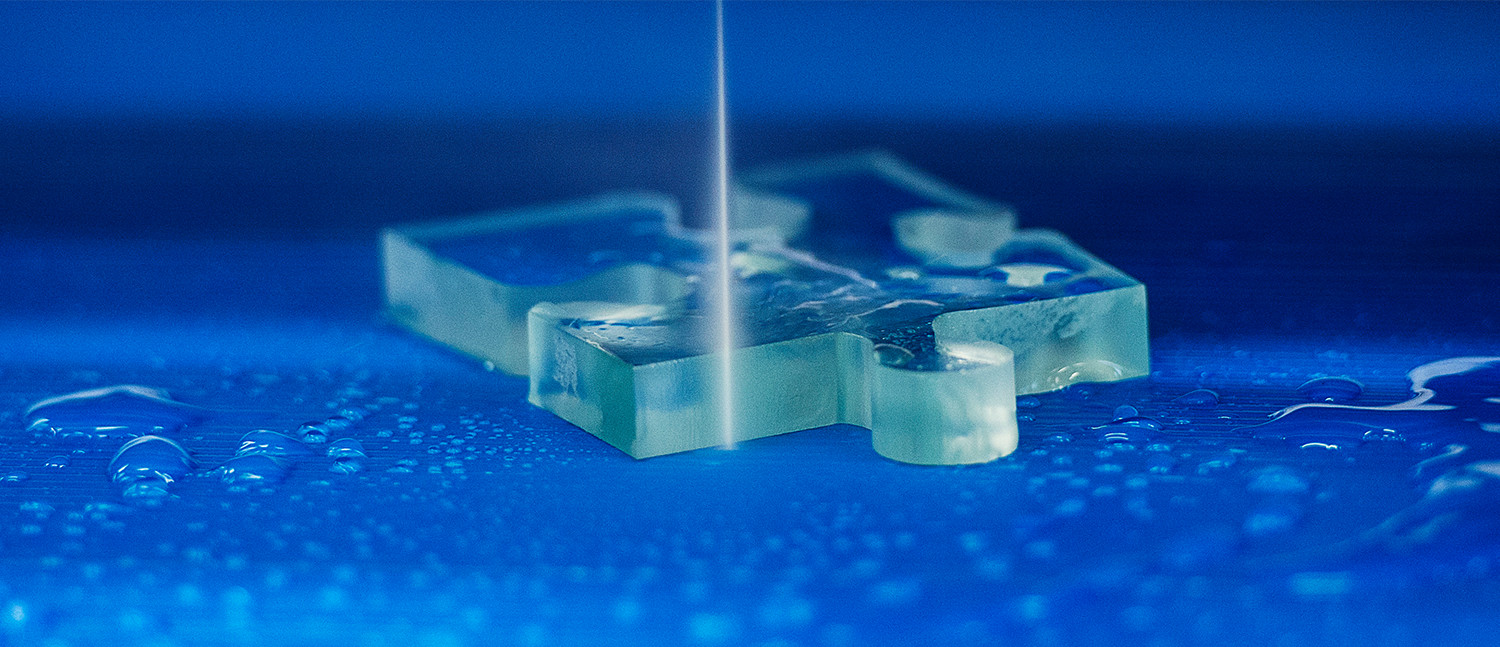

Glass and acrylic glass

Cut any shape with waterjet technology

Waterjet is an excellent choice for cutting a whole spectrum of glass products due to the fact that one process can be used to quickly transition from design to cut without tool changes. With waterjet cutting, contours and profiles can be produced that are, at best, too difficult or costly to cut using conventional separation methods. Because of its material characteristics, glass easily cracks. This makes it vital to make starting holes for the openings using as little pressure as possible. The continuous increase or decrease in cutting pressure turns out to be extremely useful when cutting brittle materials such as glass or ceramics, so that material damage can be avoided. Waterjet technology is commonly accepted as the fastest and most cost-effective way of processing glass which requires shaping and/or internal cutouts.

Waterjet is used for glass cutting applications like:

- Basic power point cutouts in glass splash backs

- Holes for door hardware

- Balustrade panels

- Stair treads

- Shower screens & mirrors

- Table top inlays

- Architectural work.

Reasons why waterjet technology is accepted as “the norm” in the glass industry are obvious:

- Waterjet is extremely fast process as compared to traditional glass cutting methods

- Waterjet produces exceptional edge quality – little additional treatment required

- Cuts preci§se internal cutouts not possible with other machinery

- Possible to cut different qualities without changing tools

- Waterjet offers operators flexibility no other process can offer

- Suitable for laminated glass, safety glass and Plexiglas

Example applications:

- Glass industry

- Blanks made of float glass, safety glass, bulletproof and fireproof glass for buildings and vehicles

- Shop-fitting, exhibition stand construction, and advertising technology

- Blanks made of glass and Plexiglas, signs, letters, and logos

- Buildings and interior construction

- Blanks made of float glass, safety glass, bulletproof and fireproof glass