Save time and material with IGEMS Camera

IGEMS camera gives you a bird’s eye view of your machine table. Unlike an ordinary camera, IGEMS camera calibrates the picture and stretches it into an exact 1:1 copy of the cutting table. IGEMS imports the exactly scaled image and places it right on the origin of your drawing. From there on, you know that the zero point of the image is the same as the real zero point on the machine.

Time saver

IGEMS camera immediately locates the sheet on the cutting table and make it visible on the table image in IGEMS CAD/CAM software. Since the zero point is already set on the table, you can quickly localize the work piece, nest the parts and start cutting job without delay.

Material saver

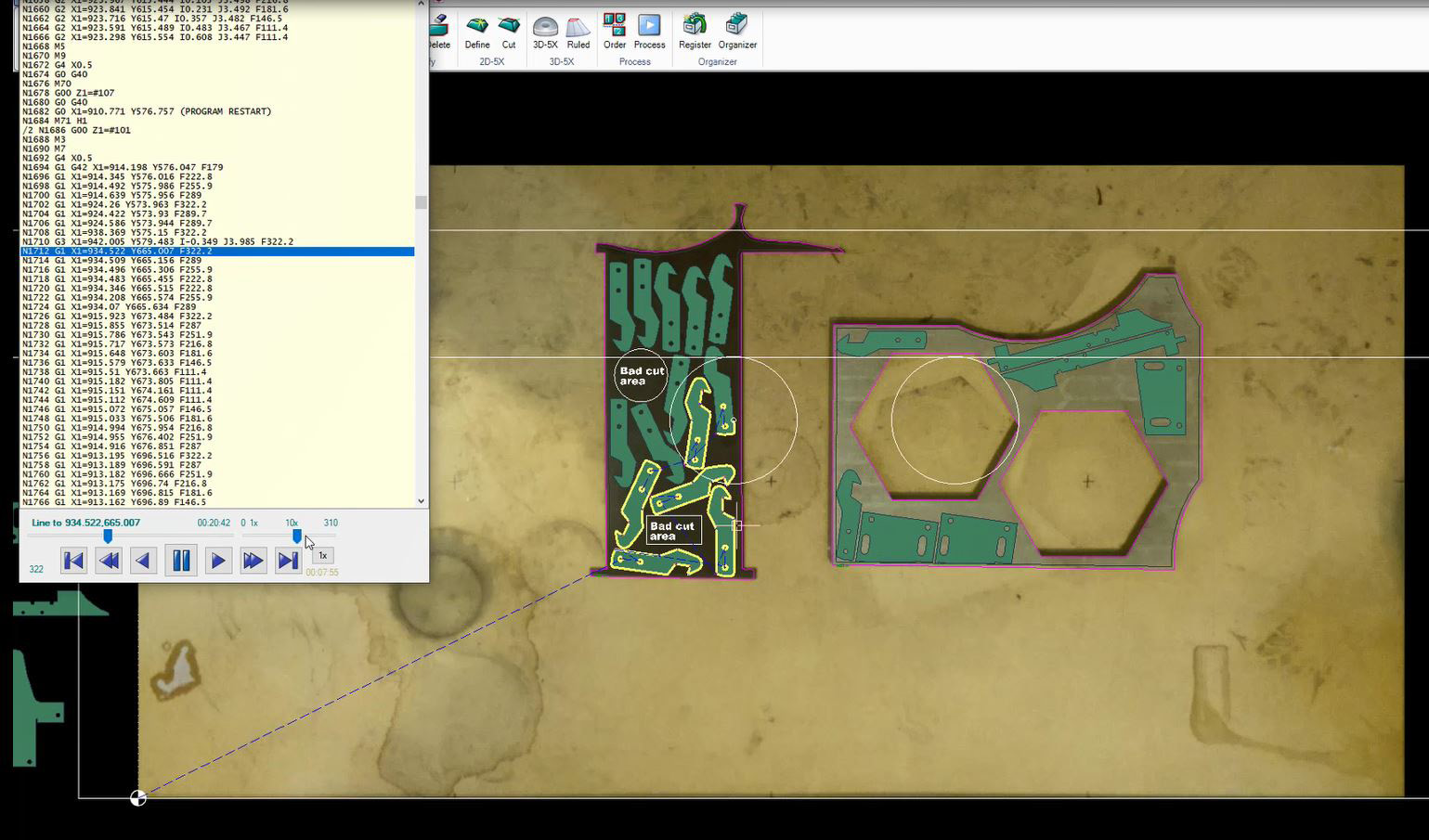

With IGEMS camera you can make more of your raw material into profitable parts. Often material sheets are partly used or damaged. With a 1:1 picture of the material sheet you easily mask the areas you want to avoid. Then use IGEMS software to optimize the nesting on the workable areas the sheet. You optimize the material usage and save valuable material from being scrapped.

Industrial Scanner

If you want to make a copy of a part, you can use IGEMS Camera as an industrial scanner. Since IGEMS camera calibrates the picture and stretches it into an exact 1:1 copy you can scan a part and quickly turn the result into a cutting job.

IGEMS Camera is an optional module for IGEMS CAD/CAM. If you wish to know more about the application please contact Customer Service at Water Jet Sweden.

Nesting in used and damaged sheet helps you to optimize material usage with IGEMS camera function.

Picture. IGEMS Camera can be added to any machine. Here it is mounted on Water Jet Sweden machine number 1 from 1993.