Grasping the opportunity for a CERN-tender

Technical ceramics & micro waterjet – Part 1

Winning a CERN tender often means a big contract and stable revenue. To win you need to meet specific requirements with high technical content and also to be price leader. This is the story about how Nanoker Research S.L, technical ceramics specialists, seized such an opportunity, stepping up in the value chain by investing in micro waterjet cutting technology.

Nanoker specializing in technical ceramics

Nanoker is a Spanish company specializing in innovation on ceramics for research- and industrial applications, delivering small scale as well as large volumes for industrial purposes. They have been in the technical ceramics industry since 2011 and working for CERN the last 6-7 years.

-With CERN we have different kinds of supplies. Sometimes they send us orders for parts in small quantities. Sometimes they launch what they call tenders open source which is public information, tells Sergio Rivera, Product and Business Development Manager at Nanoker Research S.L

CERN opens up for competition

When making tender CERN follow a formal process. First, they make a market survey to find companies able to produce the part they need. If your company fit the survey, you may present your capabilities. Then, if CERN find there is a match, you are finally invited to make a quotation for the tender.

Nanoker have had a couple of tenders in the past with CERN. One of them with really big volume of 1,3 million Euro in 1,5 years of production. In the same license Nanoker identified a new opportunity with a material called aluminum nitride, used for the detectors. CERN had launched a market survey for producing 50 000 parts. After the initial market survey, CERN identified two potential suppliers, Nanoker being one of them.

-For this tender we were producing the material, but we didn’t have any machine. The technology for cutting the parts was specified to be micro waterjet cutting technology and the company applying for the tender should have the technology in-house. You could buy the material but if you don’t have the technology, you couldn’t go for this tender, tells Mr. Sergio Rivera.

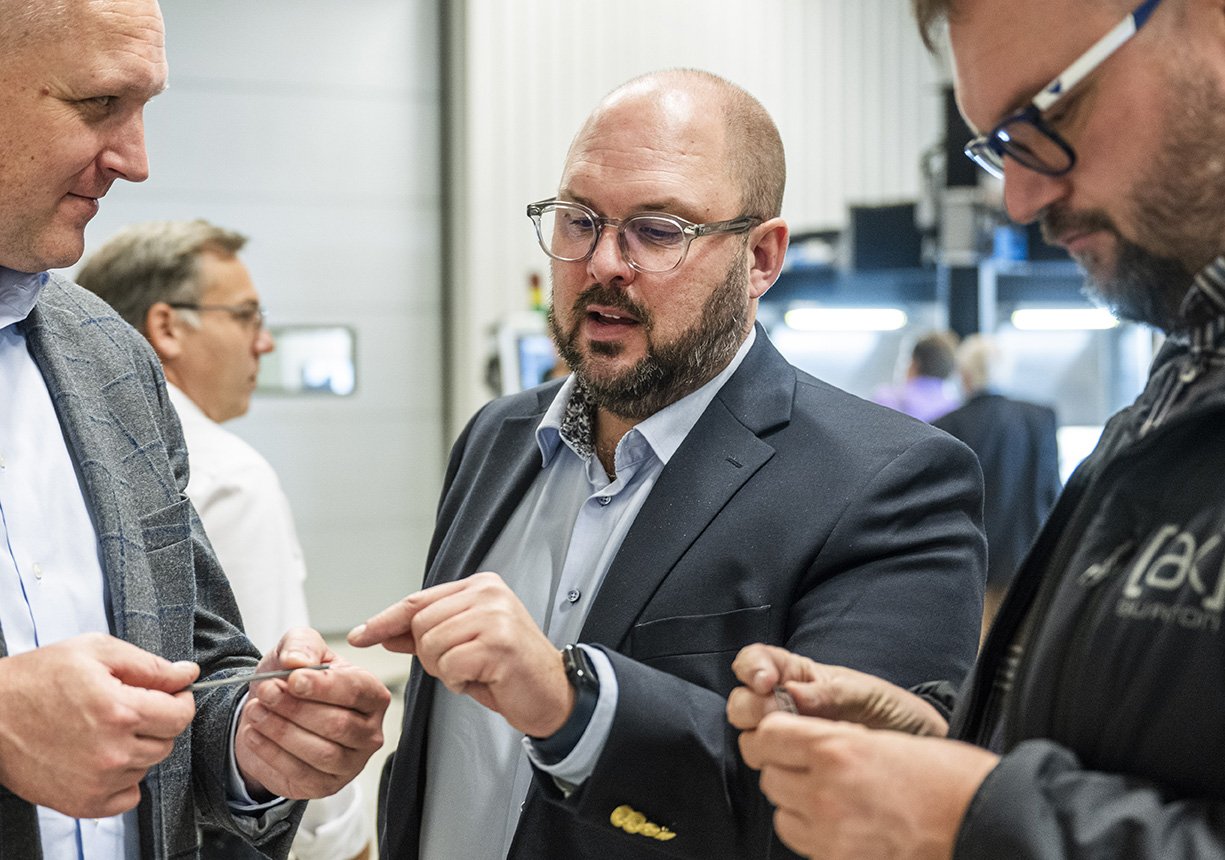

Picture: From Left, Mr. Alain Lennquist, CEO at Scandinavian representative KG Fridman AB and Mr. Sergio Rivera, Product and Business Development Manager at Nanoker Research S.L.

Business case to get the tender

At first Nanoker contacted several companies with water jet technology to make estimations for a business case and samples.

-So that’s why we contacted several companies for the water jet technology and we quoted to CERN based on our own calculations. We knew how much the material cost but with waterjet technology there is time, consumables, waste, abrasives etc., tells Mr. Sergio Rivera.

The business case that included a micro waterjet machine investment looked very positive, and they were all set to quote for the tender.

Nanoker also needed to produce parts to send to CERN to get technically homologated. There were just a few companies in the world that produce machines based on micro waterjet technology. Since two of the leading suppliers both were from Sweden, Nanoker involved Mr. Alain Lennquist, MD at their Scandinavian representative KG Fridman AB, in their quest for potential suppliers and demo parts.

Mr. Christian Svensson, Regional Sales Manager at Water Jet Sweden explains:

-When Mr. Alain Lennquist contacted us, he initially needed someone who could cut test parts for Nanoker. Parts they would send to CERN to get the tender. We facilitated contact with one of our clients who recently bought a NCM 10 Micro waterjet machine. It is equipped with our Aphajet TVL cutting tool, and perfect for the job, explains Mr. Christian Svensson.

Picture: In the middle Mr. Christian Svensson, Regional Sales Manager at Water Jet Sweden, showing parts from Micro Waterjet cutting with Alphajet TVL cutting tool.

The Water Jet Sweden client cut the test parts and Nanoker sent some samples to CERN for approval. Satisfied with the result Nanoker received good news and were finally awarded with the tender.

-Nanoker and one other company were homologated by CERN for the supply, but Nanoker was more competitive in the bid, so they were awarded with the full tender. In CERN once you are homologated technically it is best value for money that wins. The cheaper solution will get the tender. But first you have to be homologated, summarize Mr. Sergio Rivera.

With a new tender from CERN and a deadline to meet, it was high time for Nanoker to start the procurement of their own Micro Waterjet workstation, finding the company who company who deliver the best machine for their purposes. More about that in our next article, Technical ceramics & micro waterjet – Part 2: Finding the right micro waterjet for high tech ceramics.

https://www.waterjetsweden.com/

What does Nanoker Research S.L do?

Nanoker develop and manufacture products and solutions based on technical ceramics and advanced nanocomposites for various extreme applications, mastering cutting-edge materials science and industrial processing methods.

What does Water Jet Sweden AB do?

Water Jet Sweden develops, manufactures and markets advanced solutions for water jet cutting and provides a quality aftermarket offer with service and parts. Striving to be the obvious first choice for customers worldwide who seek solutions in water jet cutting where high quality, high technical content and high service standards are the basic elements.

What does KG Fridman AB?

KG Fridman AB offers a wide range of mechanical components produced by European suppliers.

Thanks to their broad network they can identify the right source for the parts you need.

Their suppliers manufacture anything from turned and milled components to springs, stamped parts, sintered parts, technical ceramics, precision ball bearings and more, all in accordance with your drawings and specifications. Several suppliers are certified EN9100 for aerospace applications, but we are also present in MedTech, offshore and other fields where requirements are challenging and components with tight tolerance.

What does it take to win a CERN tender?

When making tender CERN follow a formal process. First, they make a broad market survey to find companies able to produce the part they need. If you fit the survey, you may present your capabilities. If CERN find there is a match you are finally invited to make a quote for the tender. The company quoting the best price wins the tender.

What did Nanoker need to do to win the tender?

Nanoker already produced the material, but the parts also had to be produced inhouse. Therefore, they to plan for an investment in their own production capabilities, and present manufactured parts to get homologated technically. They made a business case to quote for the tender, found an interim partner for demo parts while the machine procurement was initiated.