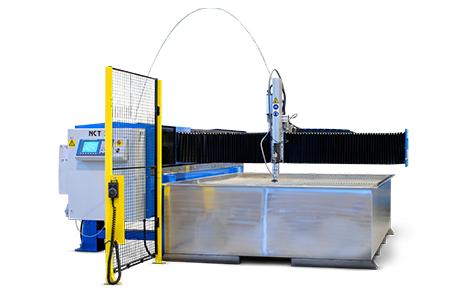

How does a water jet cutting machine work?

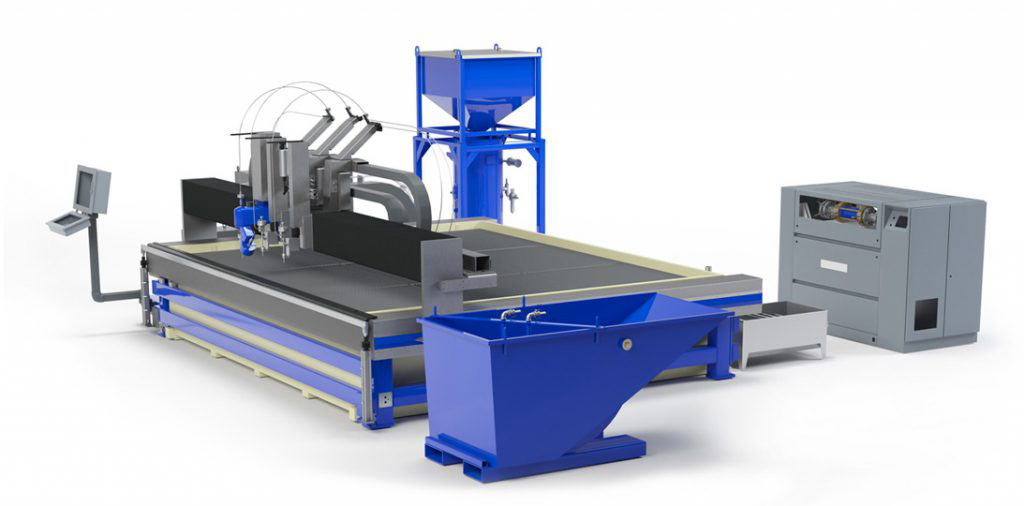

A water jet cutting machine uses highly focused water jets for cutting work. This non-thermal cutting process is as follows:

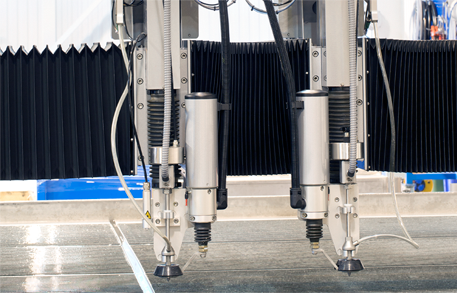

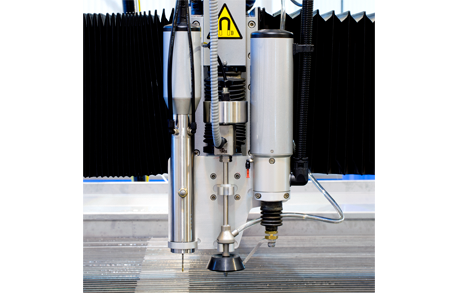

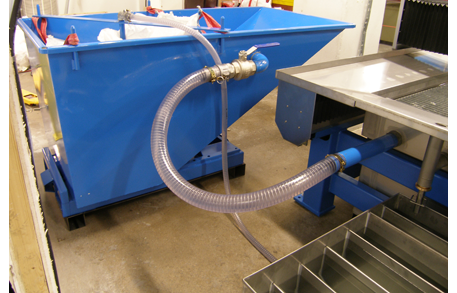

- water is filtered and fed into the cutting heads with several thousand bar pressure.

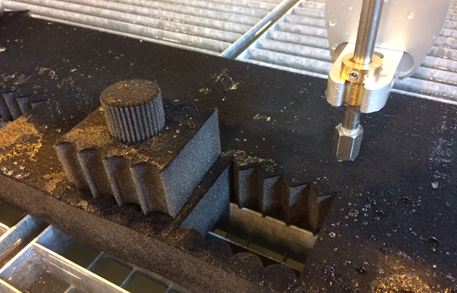

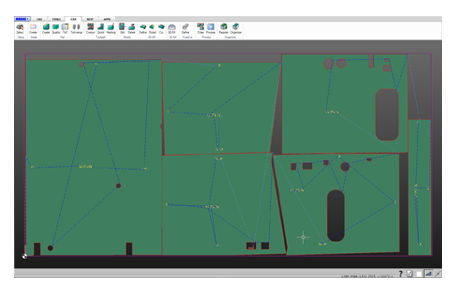

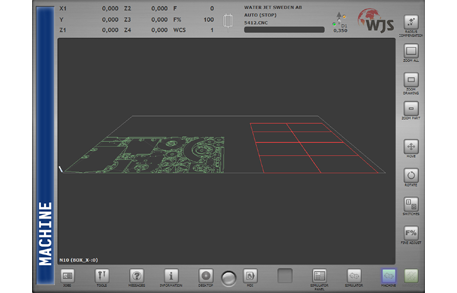

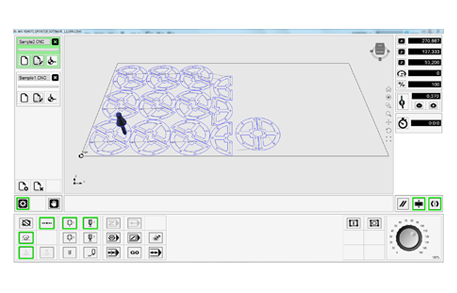

- The cutting heads move according to a fixed pattern over the material

- The focused water jet cuts

In the meantime, the material also uses abrasives, depending on the material. Thus, high-precision cuts can be carried out without thermal distortion even on materials of various types and thicknesses.

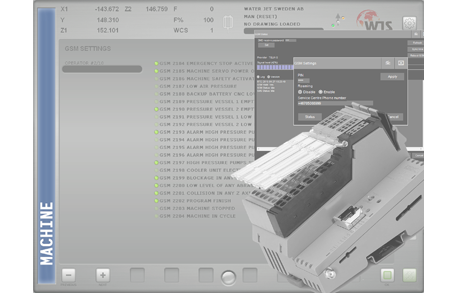

Where can I get support for my waterjet cutting machine?

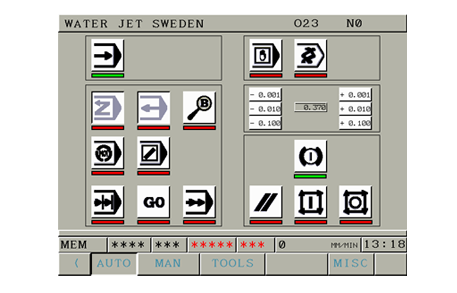

If you have problems with your water jet cutting machine, Water jet Sweden is always available for you. We offer these services around your system: 24 hours support via our hotline Original Spare Parts in custom-made comprehensive service and maintenance contracts Support in the process of expansion and relocation You need support in the operation of your Waterjet cutting machine? We also conduct appropriate training on site. Please contact us.

How much does a water jet cutting machine cost?

The costs of a water jet cutting machine vary greatly with the requirements of the customer and are therefore always determined individually. Important information on the following points:

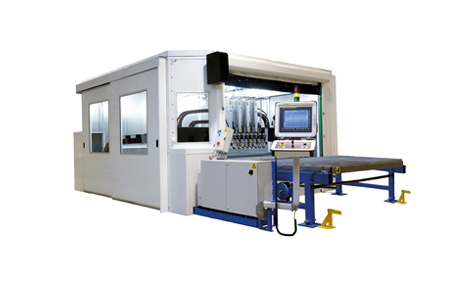

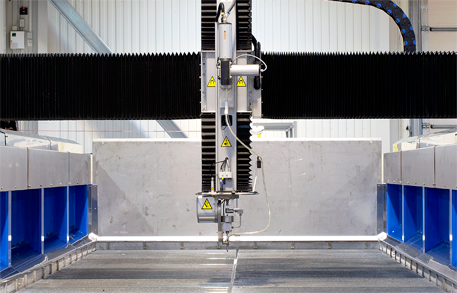

- Desired size of the working zone

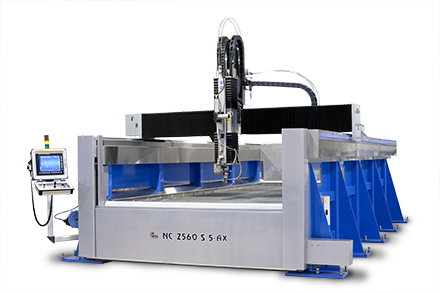

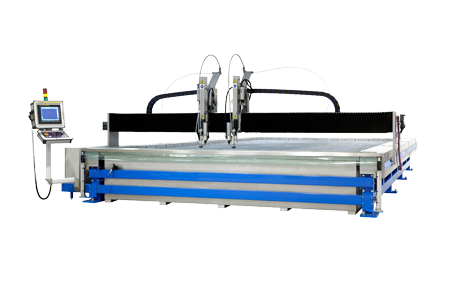

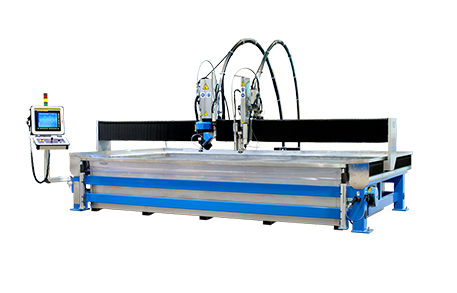

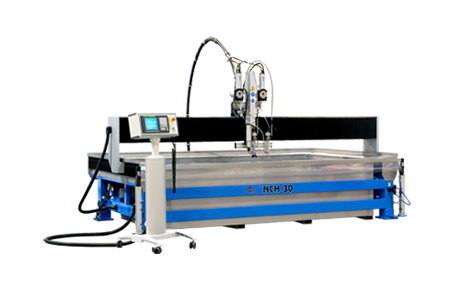

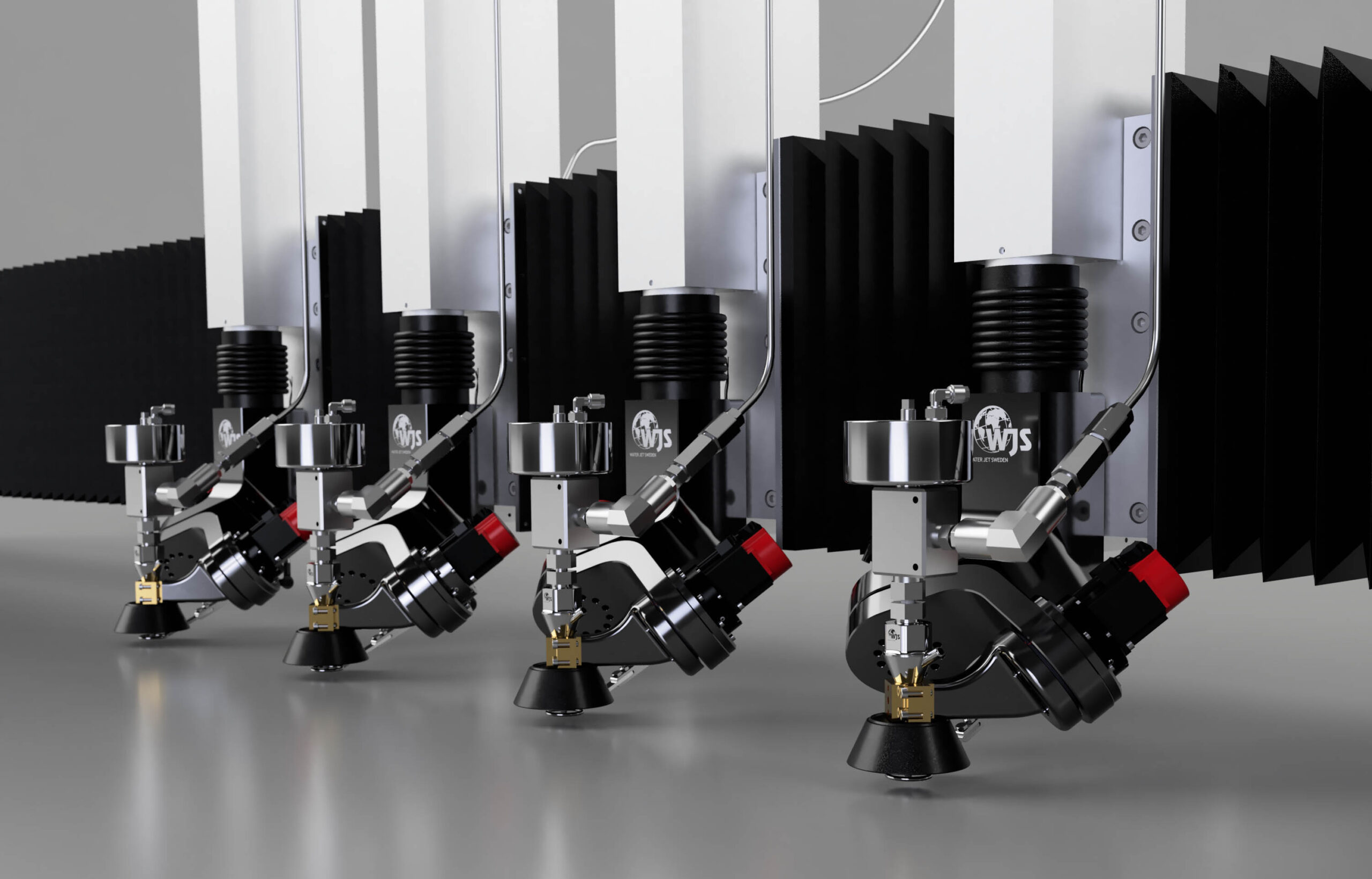

- Desired number of cutting heads

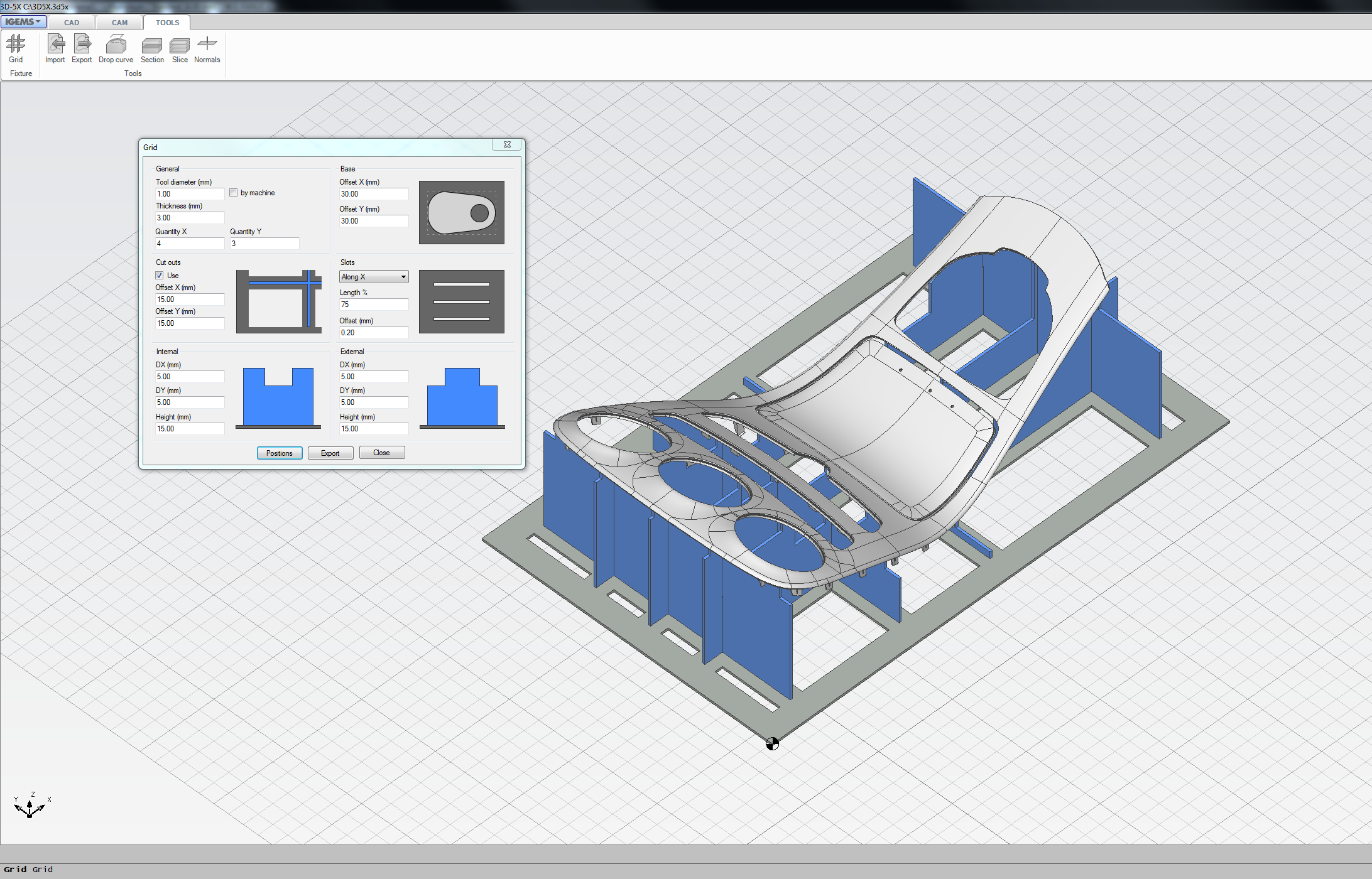

- Desired cutting method (2D / 3D)

- Material to be processed

A waterjet cutting machine can also be equipped a range of function tools and features at an added cost to support your speciifc production requirements. In addition to the acquisition costs, the cost of water, electricity, abrasives and ware parts should be taken into account in the planning.