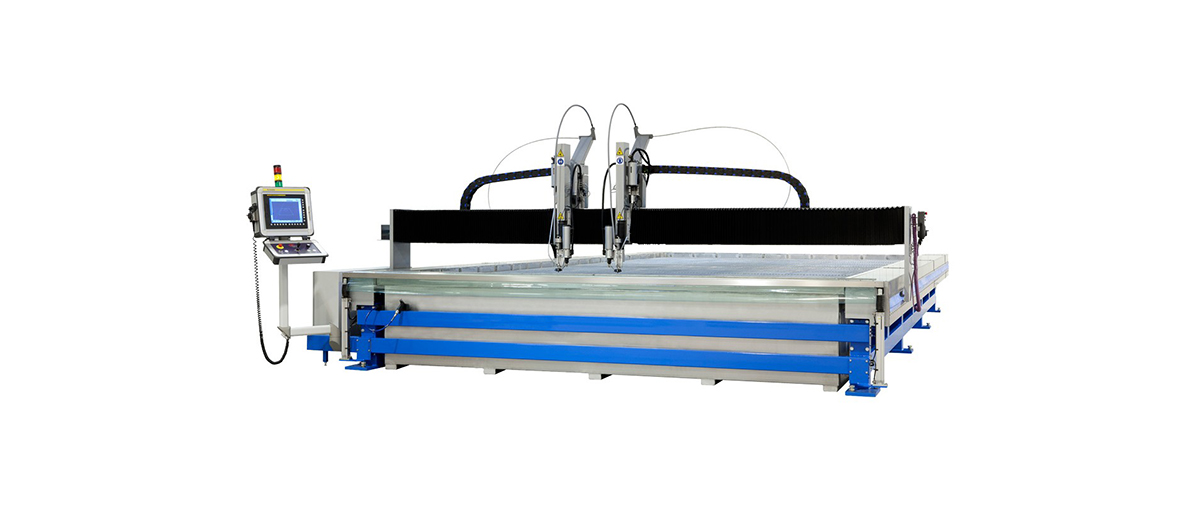

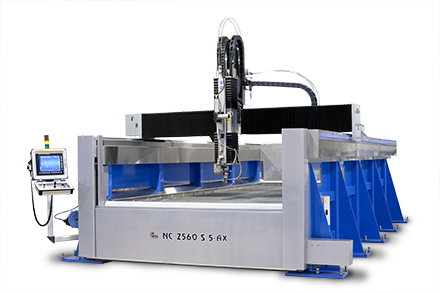

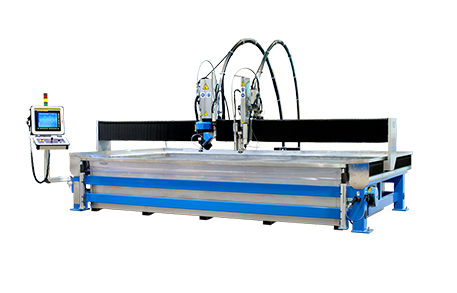

Grand

Robust, heavy duty waterjet cutting system, for all shapes, and large or odd sizes

Extremely versatile with a wide range of design options. Grand offer the largest tables sizes with a robust heavy-duty design to manage large and odd size materials. Thanks to our worldwide patented guide system all machines have the same tolerance, independent of size. You get the same high performance from a 12 meter machine as from a 2 meter machine.

The Grand machines popular in specialized job shops and as workstation in industry production lines. Each machine is tailored to fit the customer process requirements, easily adopted for multi-job processing and unmanned operations.

Characteristics:

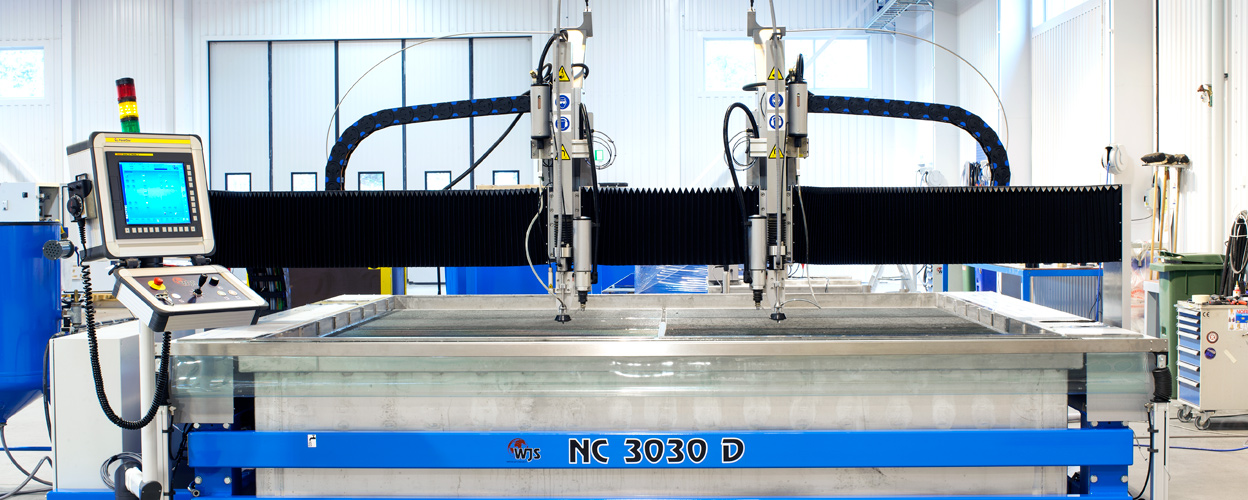

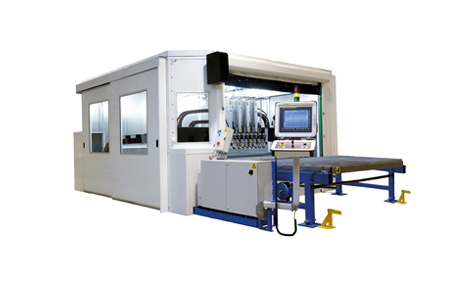

- Protective Design Features – side mounted motion system enable safe handling of large and heavy materials and heavy duty stainless steel covers protect from impact.

- Efficient Job Handling – access from three sides enable easy loading and unloading and Zone Divided Worktable option make it possible to exchange jobs while processing.

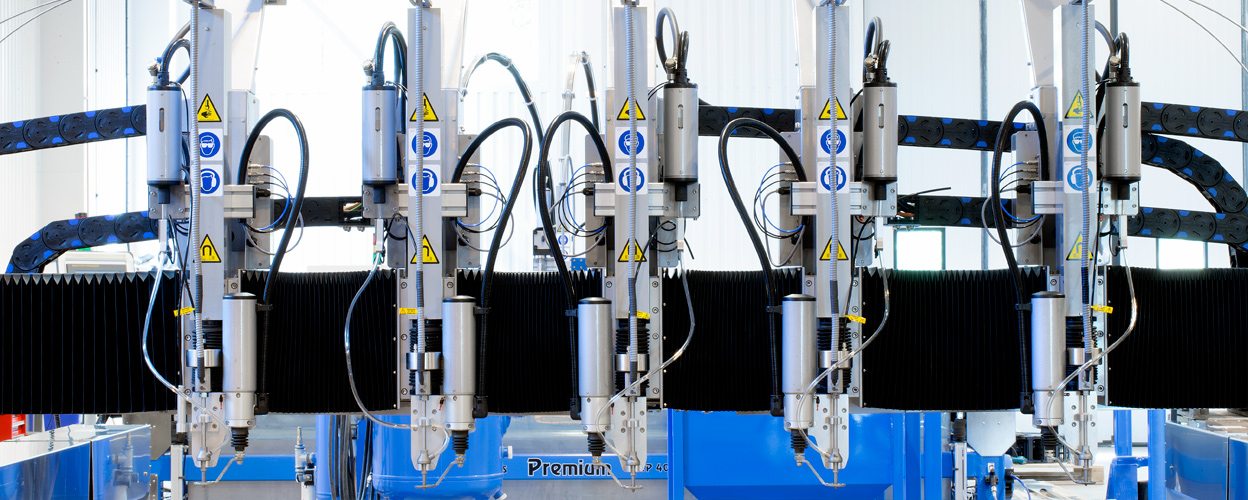

- Heavy Duty Production Options – To avoid backlash and support thick and heavy materials there are options like Quick Water Level Adjustment and different table grids.

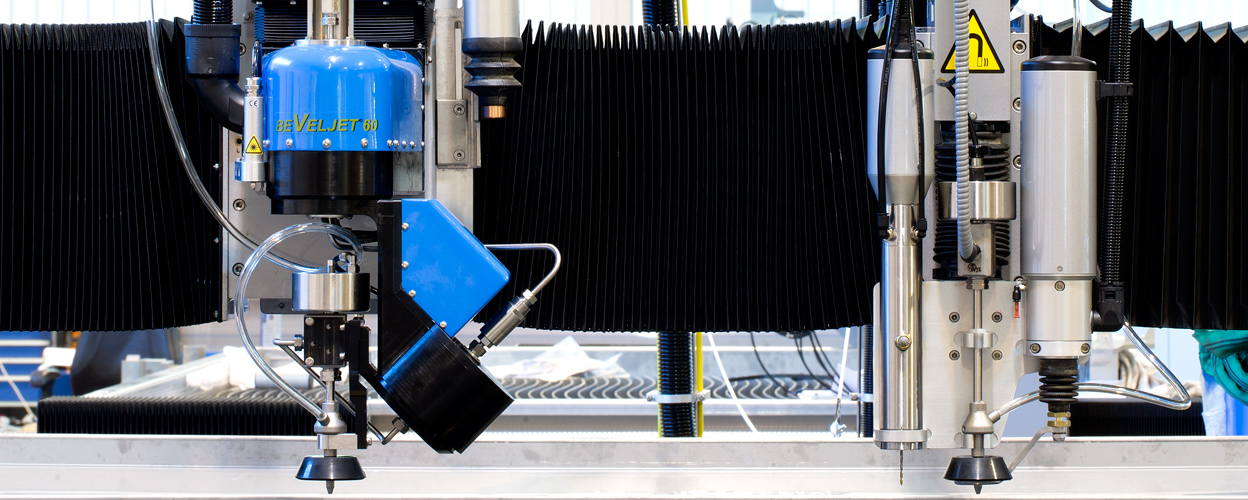

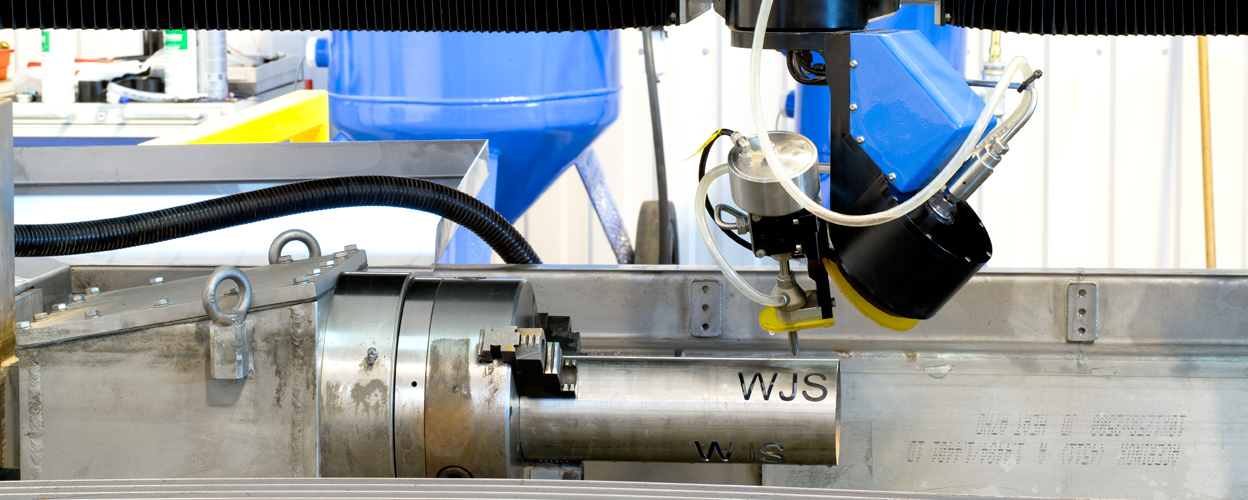

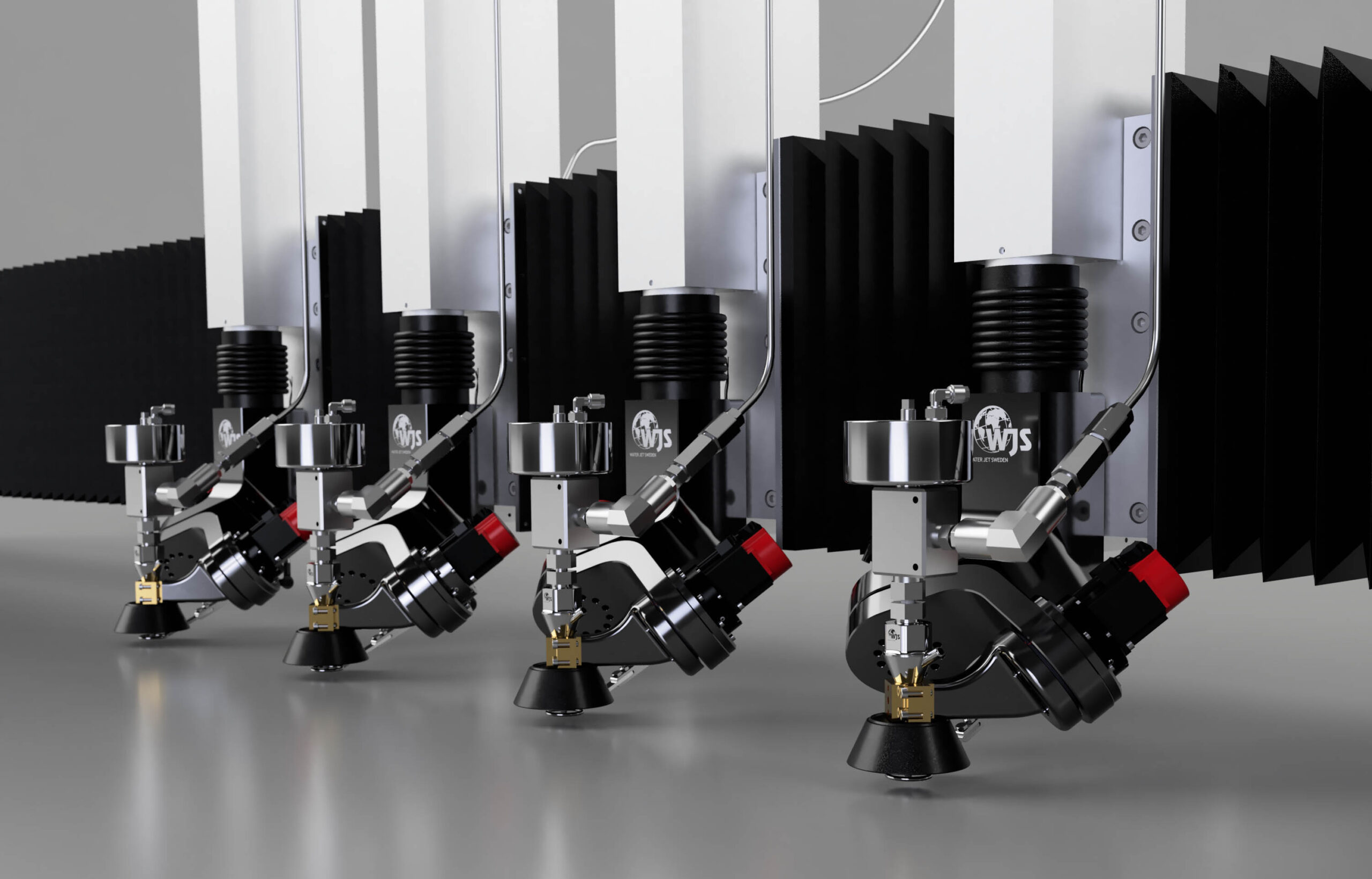

- Beveljet®60 – Real five axis interpolation to manage bevel and free form 3D cutting. A fully vector based calculation in Fanuc for TCP improve cutting quality. Combine with one or several 2D cutting heads.

Contact

Specifications

Technical Data

Machine Performance

Features

Beveljet®60 Cutting Tool performance

Five year performance warranty

We guarantee that all our machines keep the same tolerance level after five years as when the machine was first delivered.

Lifetime support by waterjet specialists

Our service team is highly specialized within the field of water jet cutting. Via our hotline support, our technical expertise is available on a 24/7 basis.