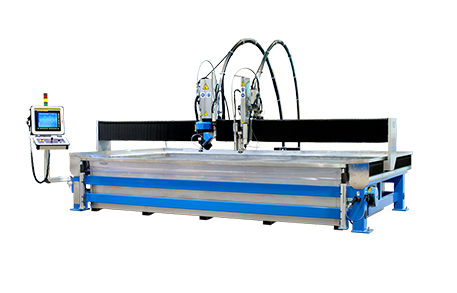

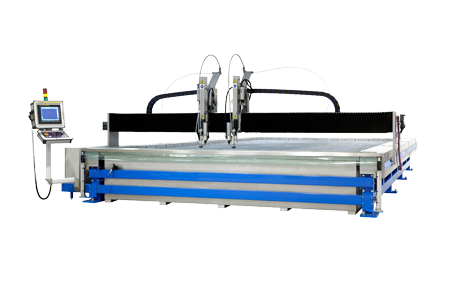

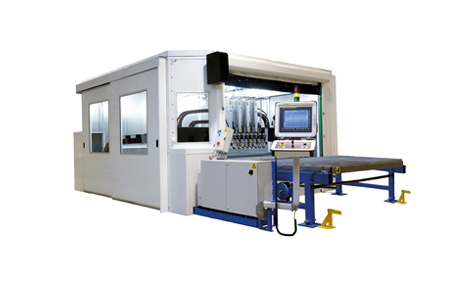

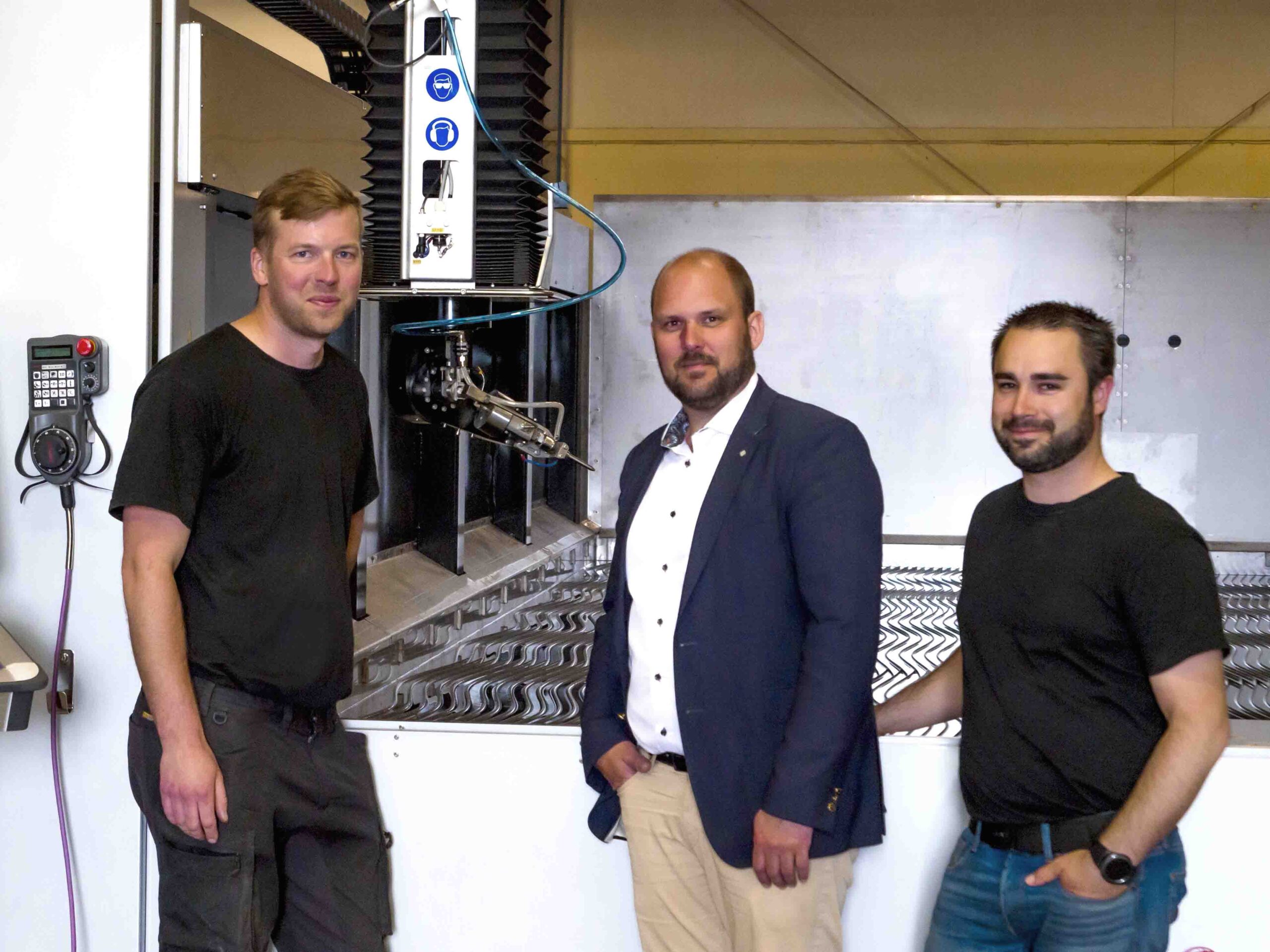

FiveX / FiveX Ultra

Forefront technology for advanced free form cutting

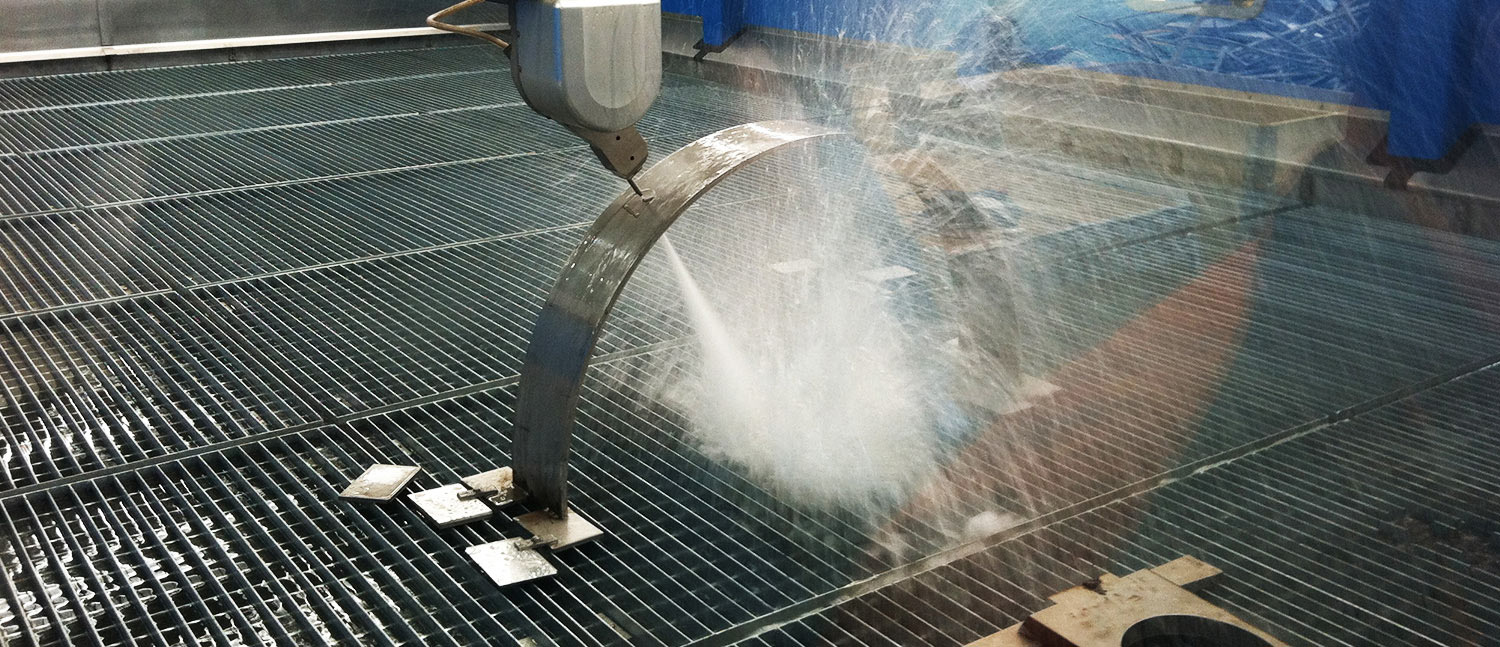

FiveX machines are commonly used in high tech industry sectors, built with our most advanced technology and with an exceptional stable design to be able to repeatedly perform high precision free form cutting of full 3D components.

Large-scale 5-axis processing allows the advantages of the waterjet process to be utilized in the finishing of fabricated structures, pressed parts, molded composite parts and other 3-D parts. With Z-Axis capacities up to 1500 mm and a generous working area, the waterjet technology has been embraced largely by the Defense Industry, Space Industry, Aerospace Industry and Power Industry. FiveX Ultra is more compact and suitable for high-tech mechanical workshops in general. Designed materials such as Hardened Steel, Titanium, Kevlar and Carbon Fiber can easily be cut to precise form. Applications include trimming of molded parts into their final shape.

Characteristics:

- Free form cutting – utilize free form cutting with an exceptionally long Z-movement up to 1500 mm. specially designed fixturing tables on request.

- Intelligent Probe Interface – The Work Piece Indicator (Renishaw Probe Interface) is integrated with a large library of pre-designed measurement cycles, and customized measurement cycles can be delivered as an option.

- Customer-specific fixtures – if there is a need, we create fixtures according to the customers’ specific cutting needs, as part of the total solution.

Contact

Specifications

Technical Data FiveX

Technical Data FiveX Ultra

Performance

Features

Five year performance warranty

We guarantee that all our machines keep the same tolerance level after five years as when the machine was first delivered.

Lifetime support by waterjet specialists

Our service team is highly specialized within the field of water jet cutting. Via our hotline support, our technical expertise is available on a 24/7 basis.