Learn more about water jet cutting

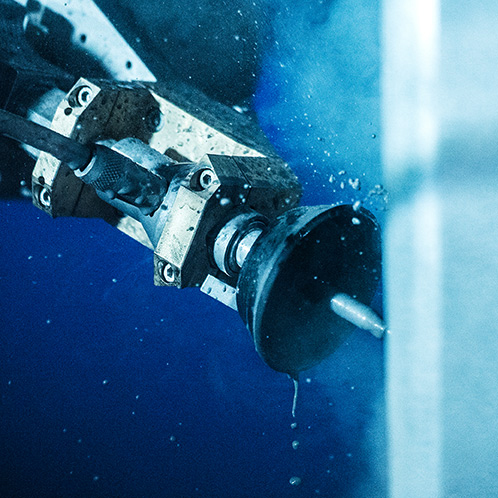

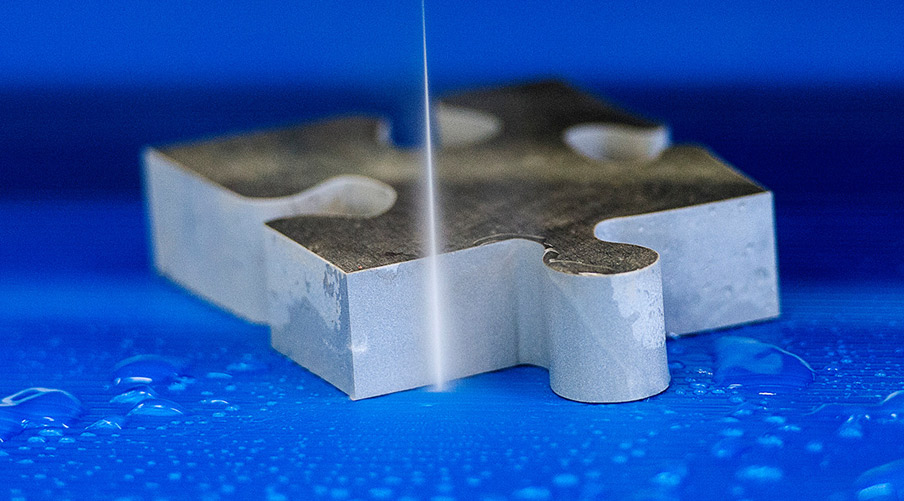

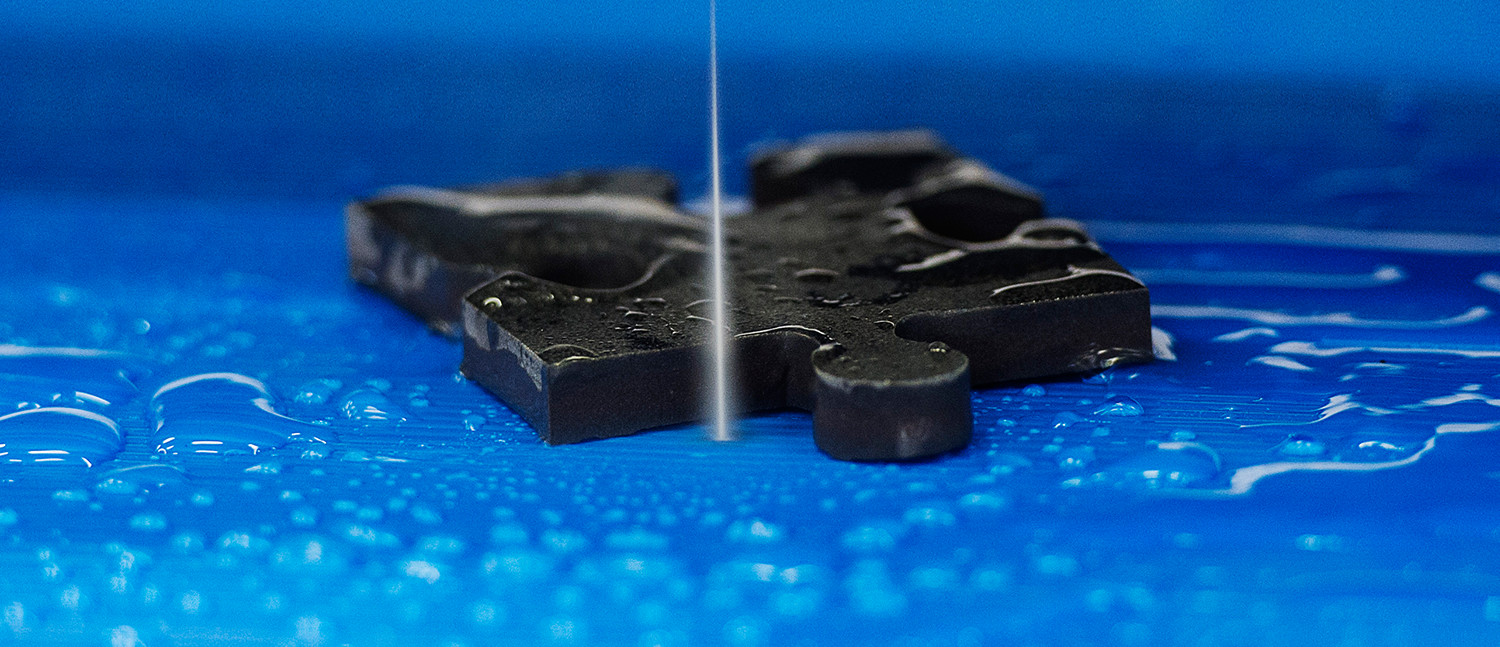

Waterjet cutting is a non-thermal cutting method using only natural sand and water to cut almost any material. In theory a simple process but in practice an advanced cutting technology. The brittle cutting process give a smooth cutting surface with no slag or heat affected zones, and there is less need for post processing.

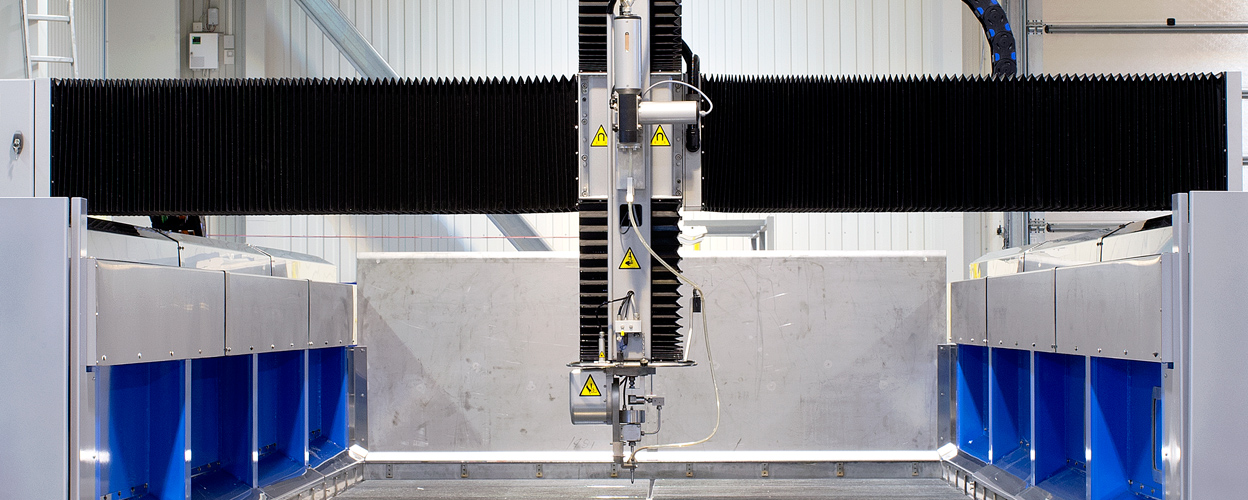

All materials can be cut by the one and same waterjet machine, from soft rubber and plastics to the hardest metals and ceramics. A CNC operated waterjet machine ensures identical parts independent of volumes and with a minimum of waste material. The versatility and ease of operation makes waterjet technology compare to no other machine tool process in the market.

What do you want to learn more about?

There is a wide range of materials, applications and industries where waterjet cutting has become a useful machine tool process. These are some examples.

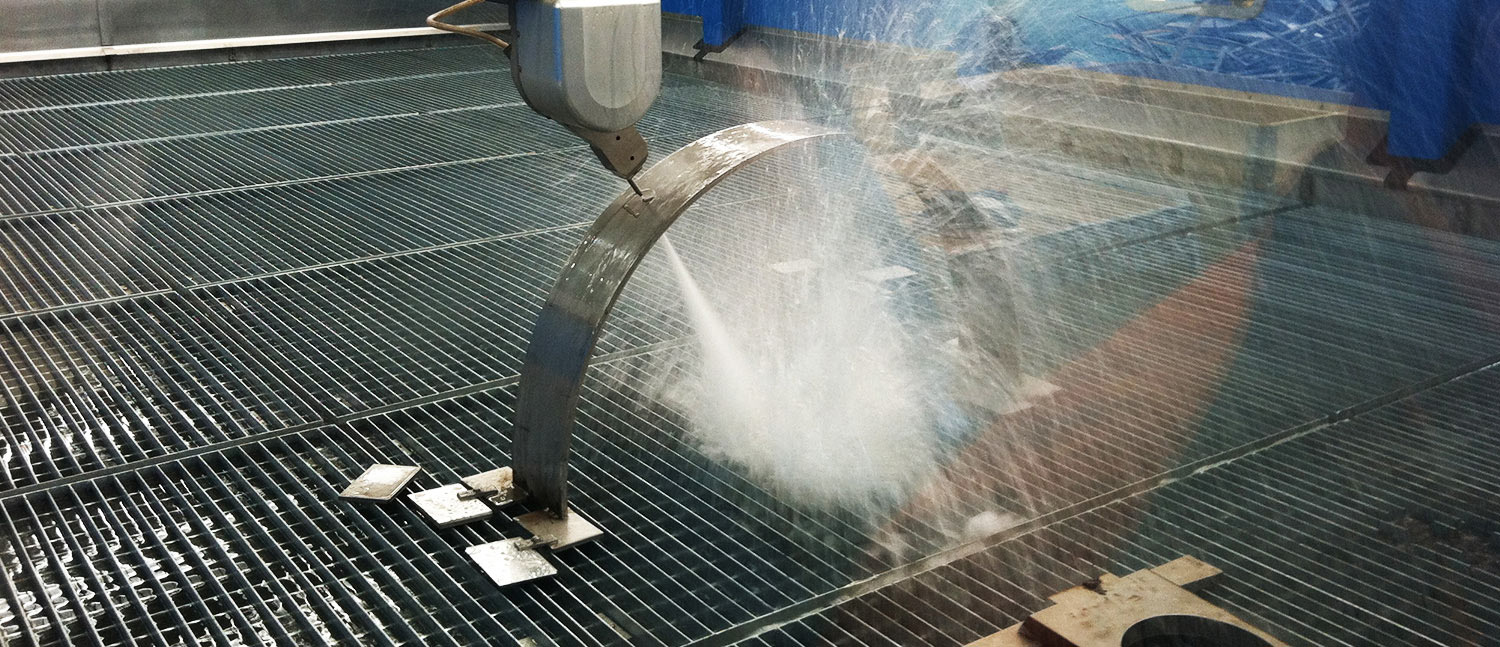

Metals

A cold cutting method offering unique benefits

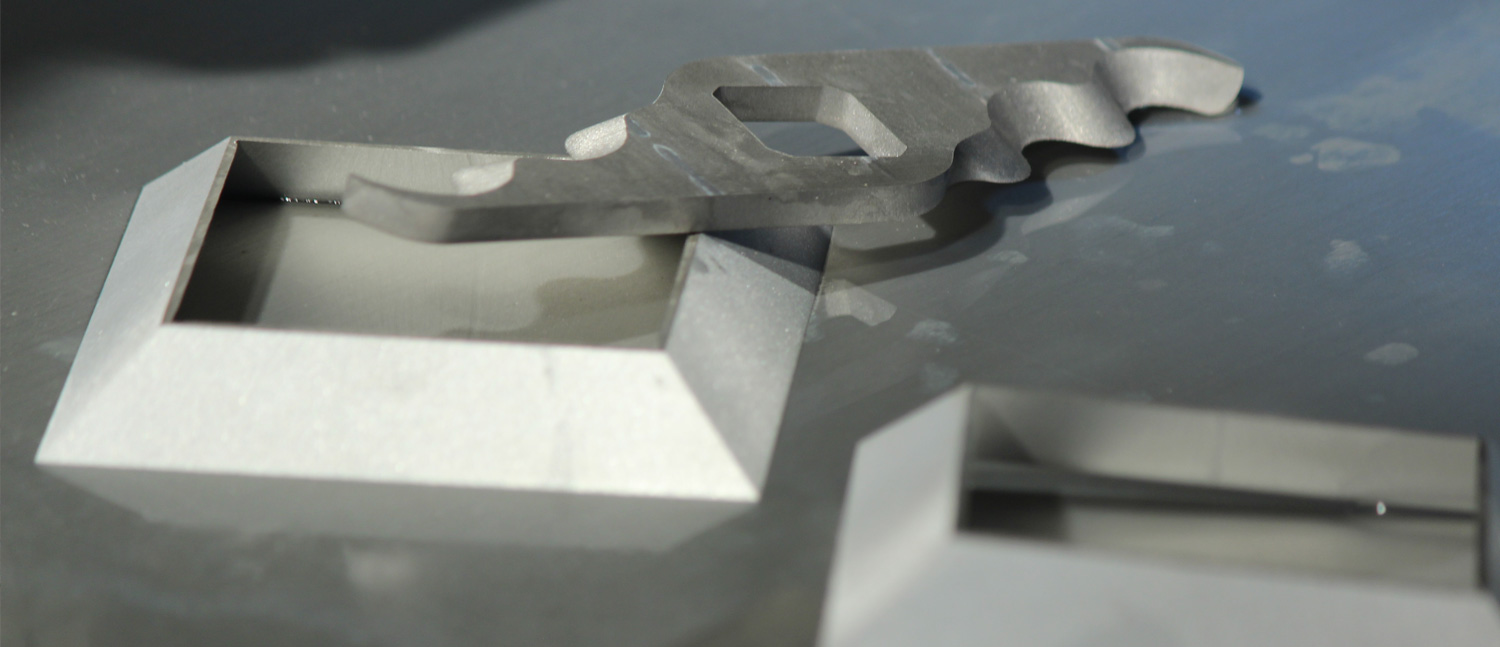

Metal cutting by the Abrasive Water Jet cutting process (AWJ) is a major area of application for water jet technology. Metals such as steel, stainless steel, Hastelloy, Hardox, Weldox, Inconel, titanium, aluminum or nonferrous metals. Finely grained sand combined with the ultra-high-pressure water beam creates a powerful cutting tool, cutting up to 300 mm thick metal into any shape. This is a cold cutting process with fine cuts and very little additional work needed.

A water jet system offers outstanding flexibility and is easily adjusted for each specific cutting requirement. Use one or several cutting heads. Use 2D or 3D cutting and add some functional tools for added efficiency.

Metals – Ferrous Metals

Metals – Aluminum

Metals – Other non-ferrous metals

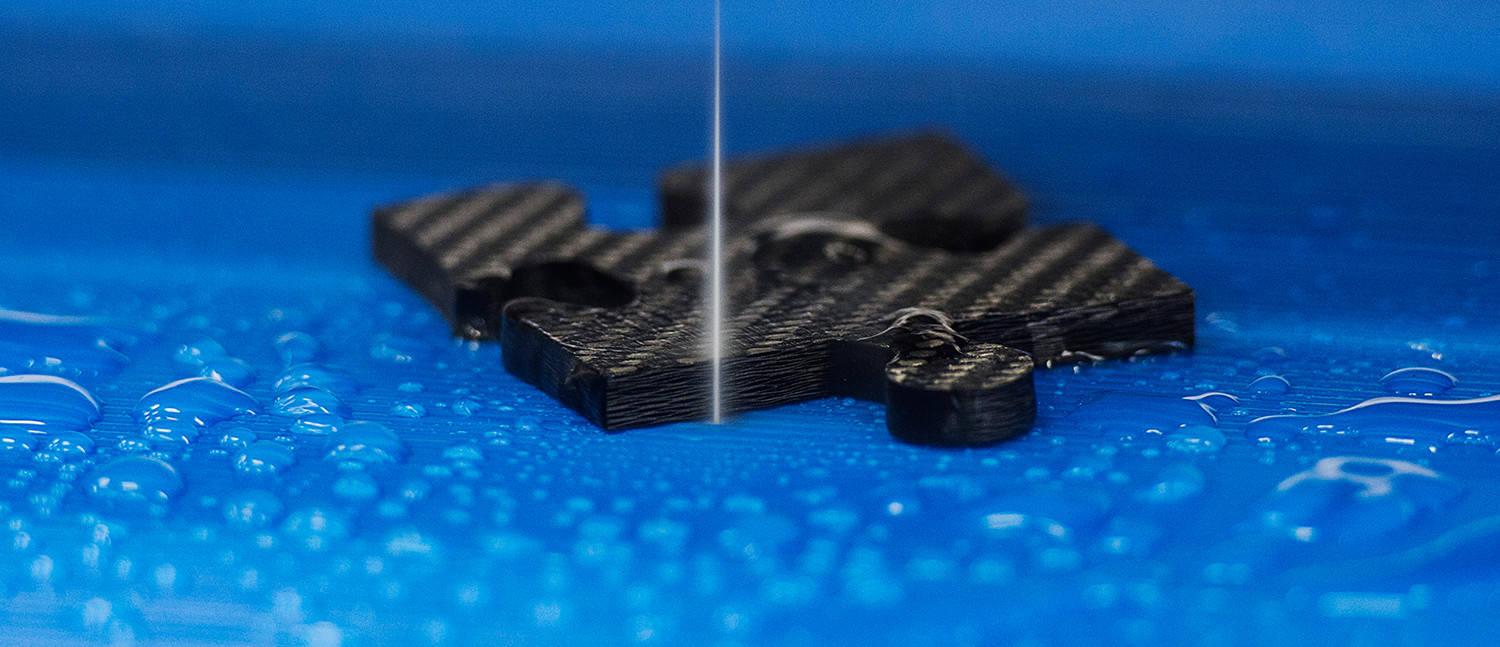

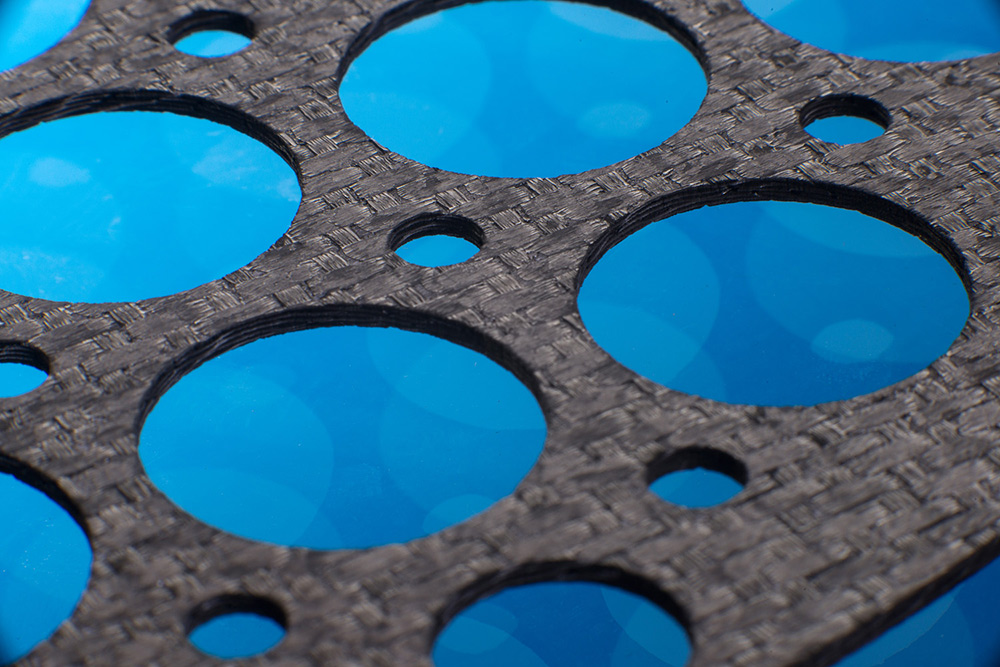

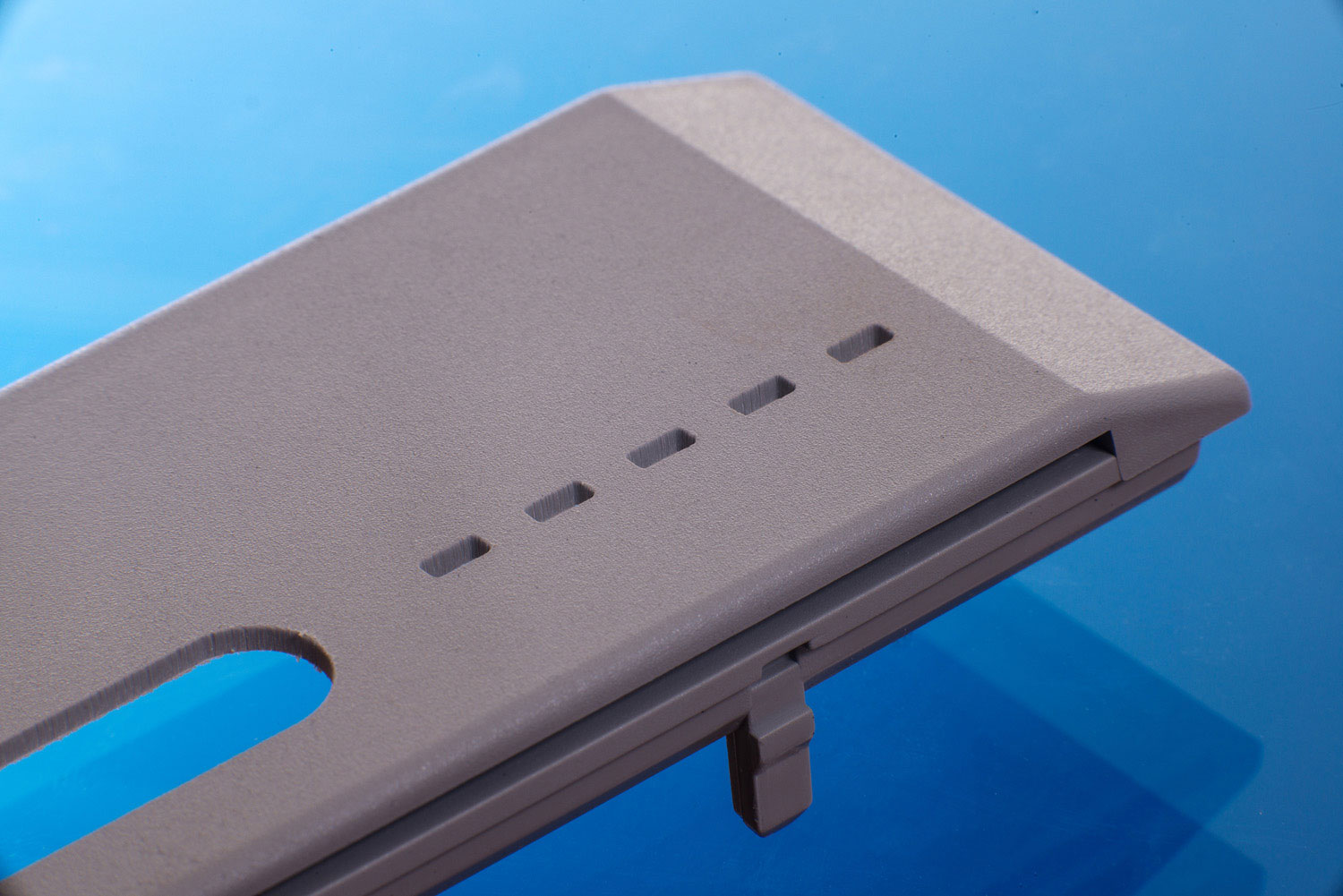

Composite materials

Less tool wear and almost any shape

There is an increased use for composite materials in many industries, yet there are few machine tools that are really suitable for processing these materials. One major challenge is tool wear. Usually, water jet cutting implies no extra tool wear and also offers the option to cut almost any shape. This is why this technology is widely considered the best alternative for composite processing.

The term composite comprises a wide range of materials with different characteristics: Kevlar, carbon fibre, glass fibre, non-woven materials, composite resins, etc. Therefore, what cutting process will turn out most efficient depends on the the material – Abrasive Water Jet cutting (AWJ), Fine Abrasive Water Jet cutting (FAWJ) or Pure Water Jet cutting (PWJ).

Glass

Cut any shape without cracking

Standard glass, composite glass, armored glass or Plexiglas®? For years, glass has been a frequent application area for water jet cutting. Diamonds may cut straight lines, but when it comes to curved shapes, water jet is a natural priority.

Glass is sensitive to cracking and requires careful handling. Use special cutting programs with low-pressure piercing and cutting tables adapted for smooth handling. In order to avoid chipped cutting edges, it is also important to use quality abrasives.

Let us find the best cutting solution for you.

Stone and Tiles

For architectural design and artistic work

Water jet solutions cutting stone, tiles and other ceramic materials into different shapes are used all over the world. Applications spans from comprehensive architectural structures and specific interior design elements to unique installations of public art.

Using a water jet machine for free-cutting, you can easily transform most stone materials into almost any shape. The only limits will be set by your own creativity.

Let us find the best cutting solution for you.

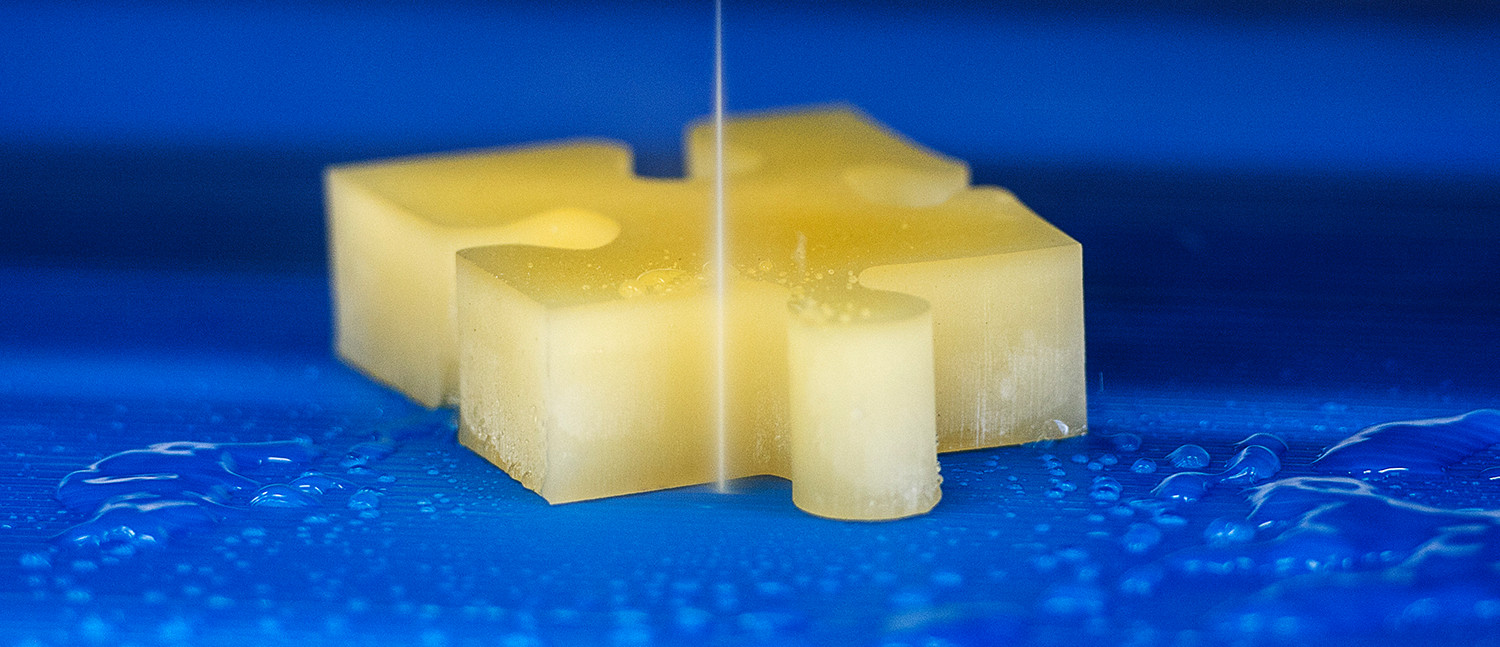

Rubber and plastics

Efficient production from small to large series

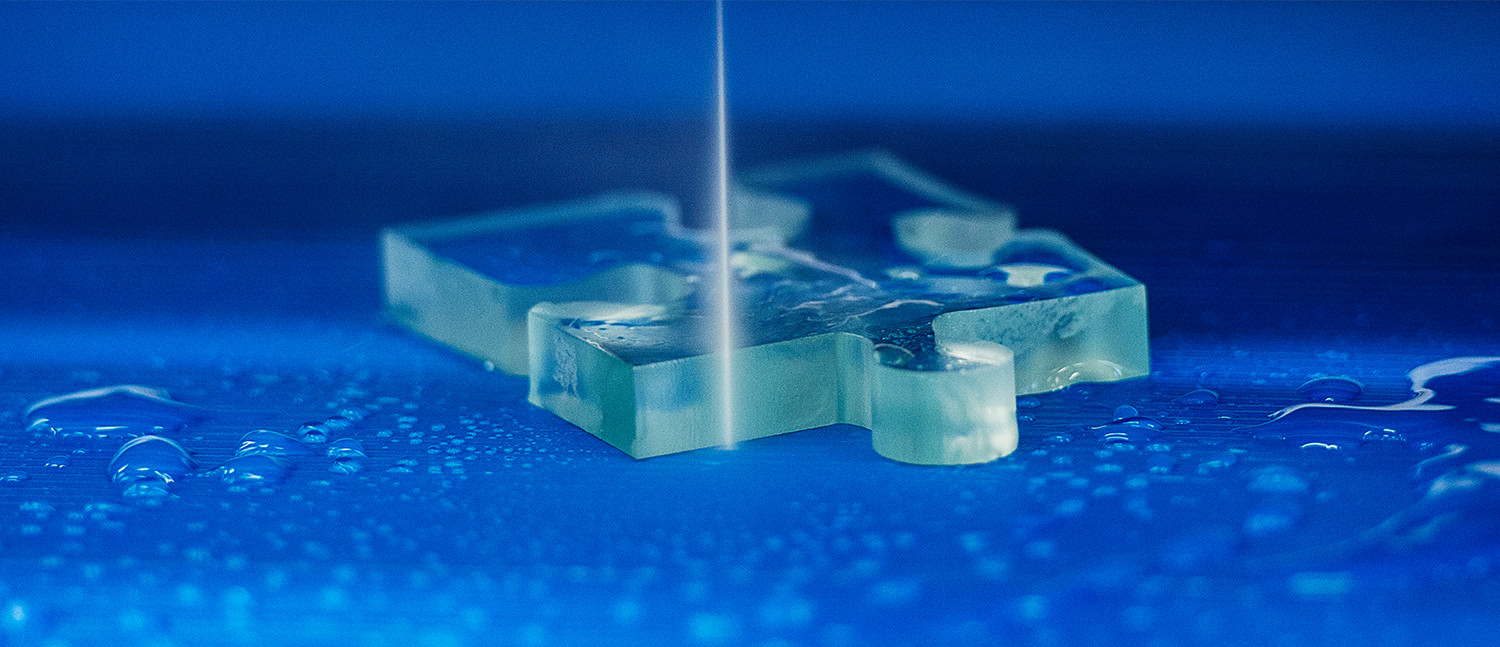

When cutting soft materials like rubber, plastics and foam, there is no need for abrasives. For soft materials, the pure water jet cutting process (PWJ) is a priority alternative. PWJ cuts rapidly with very narrow cuts of 0.1 mm

When it comes to soft materials, the water jet technology brings benefits for both small- and large-scale production. There is no need for punching tools. With simple CNC programming you can produce one single part quickly – and with a beam you can mount a large number of parallel cutting heads, thus cutting very large volumes simultaneously.

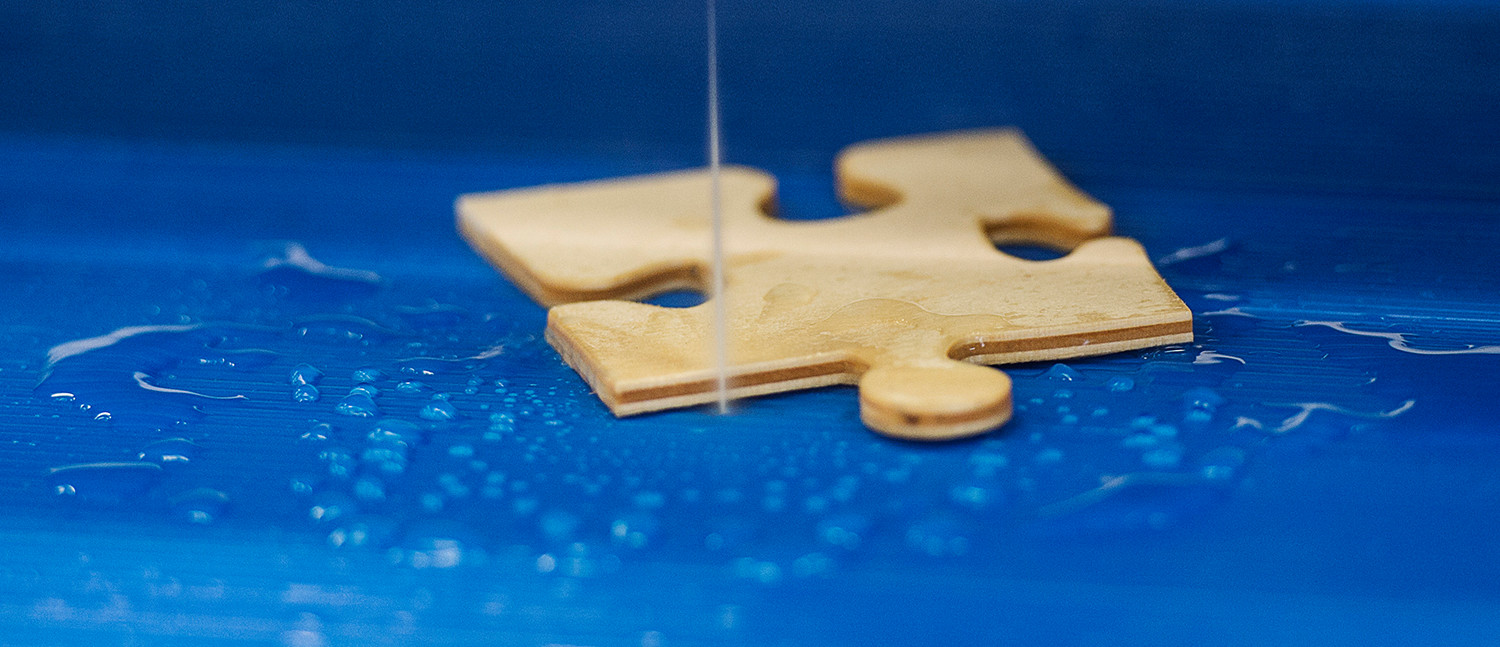

Wood

Fabricated wood materials, e.g. veneer and plywood

Processing of wood has become something of an established niche application for the water jet technology, and there are some application areas of specific interest. The wood materials most frequently used today are fabricated ones, like veneer and plywood. Fast setup time, narrow cuts, no splintering and easy free-form cutting are some of the documented benefits when applying water jet cutting for these materials.

Water jet technology has been used e.g. for the production of wooden jigsaw puzzles, table tennis rackets and wooden furniture – and there is a lot more to come.

Full 5-axis processing

Shaping 3D components in different work planes

Large-scale 5-axis processing allows the advantages of the water jet process to be utilized in the finishing of fabricated structures, pressed parts, moulded composite parts and other 3-D components. With Z-Axis capacities up to 1000 mm and a generous working area, the water jet technology has been embraced largely by the defence, space, aerospace and power industries.

Major aero engine manufacturers have turned to 5-axis water jets to produce apertures in titanium. Using water jets, they eliminated stress in the material and in a hardened state left the edges without heat-affected zones.

Flexible Bevel Shaping

2D sheet materials turned into 3D parts

Beveljet® 60 takes your water jet machine to a new level. In its most basic form it can easily be programmed from a 2-D cad file in order to create a variety of bevels on the plate edge – a measure often required as preparation for welding. Full 5-axis articulation allows these bevels to follow the contours of the profile without need for templates or any specific 5-axis programming.

Market leading customers have been able to rationalize their processes while improving dimensional quality by the introduction of Beveljet functionality, thereby reducing lead time by several working days and eliminating the frequent errors associated with multiple setups.

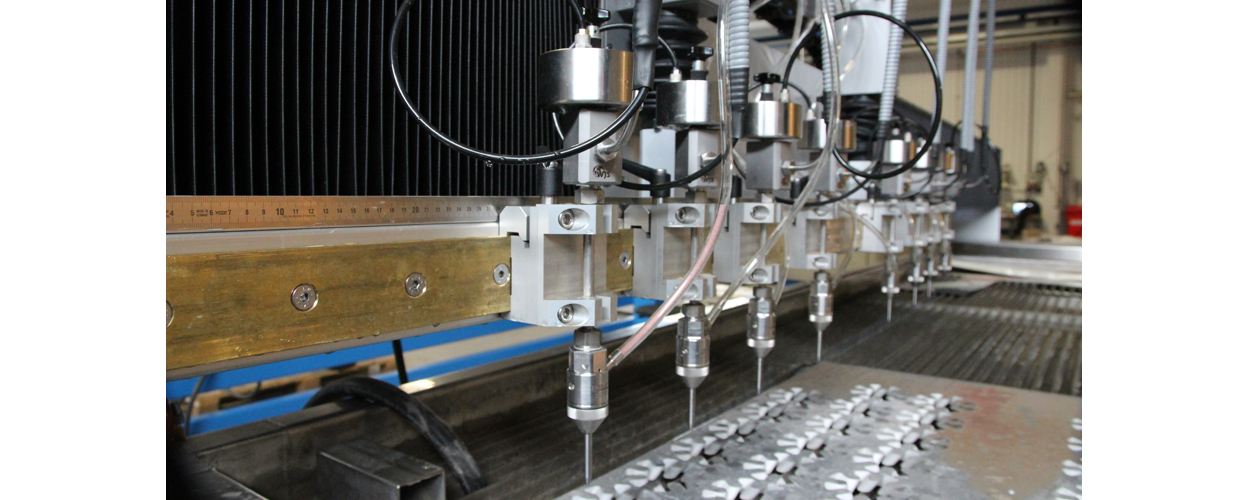

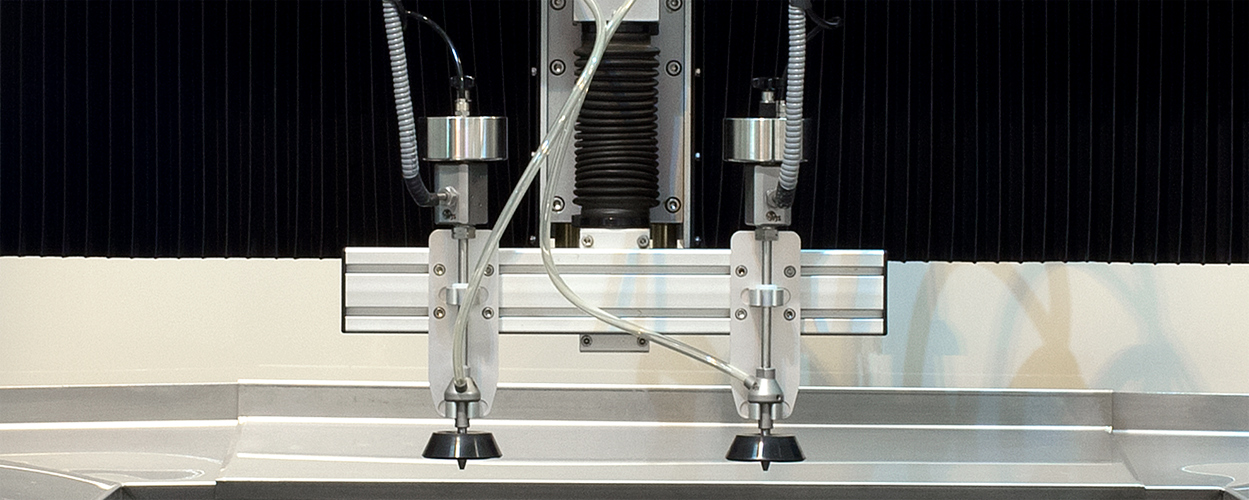

Multi Head CNC Controlled

Automatic CNC repositioning of multiple cutting heads

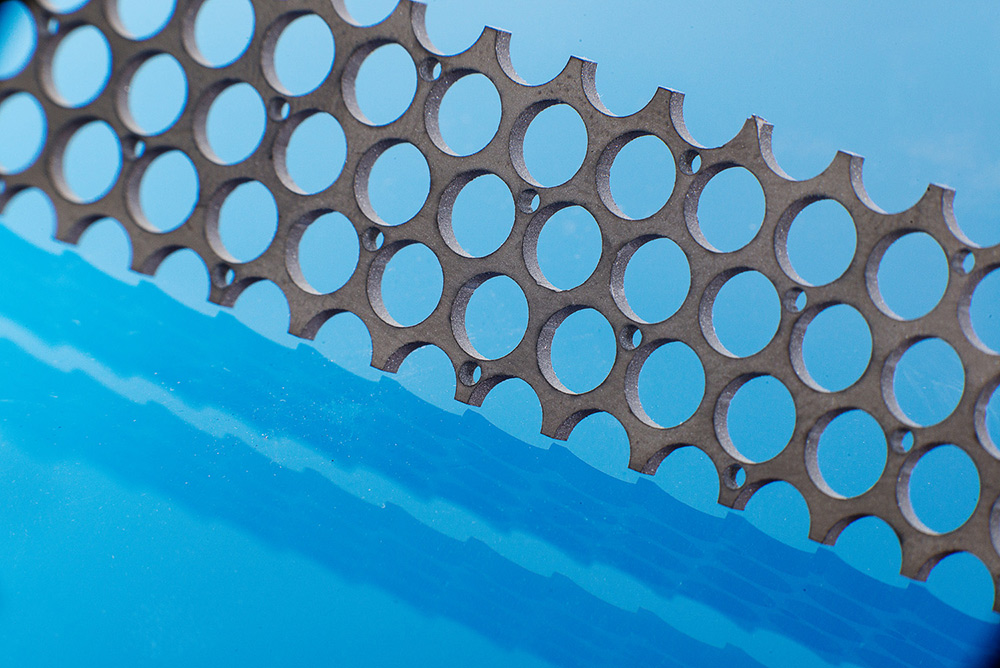

Application where the user needs the flexibility to cut a wide range of disparate parts from the same parent material.

Automatic repositioning of the cutting heads in CNC mode allows for the best material utilization and productivity. The cutting program can frequently utilize some heads to cut a pair of large parts, then use the other heads to process parts simultaneously out of the same material sheet.

This is made possible by the use of Fanuc linear drives on each cutting carriage, with positional guidance from high-resolution Heidenhain linear scales.

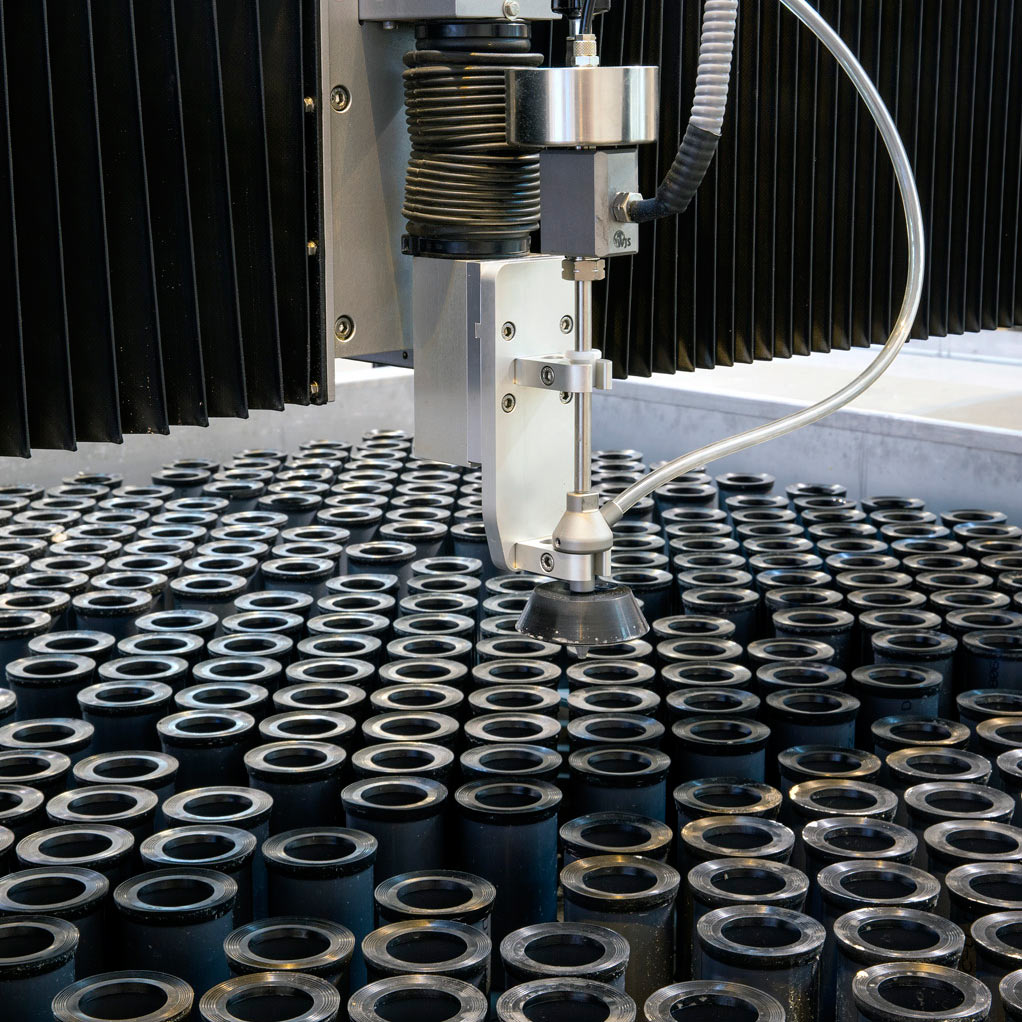

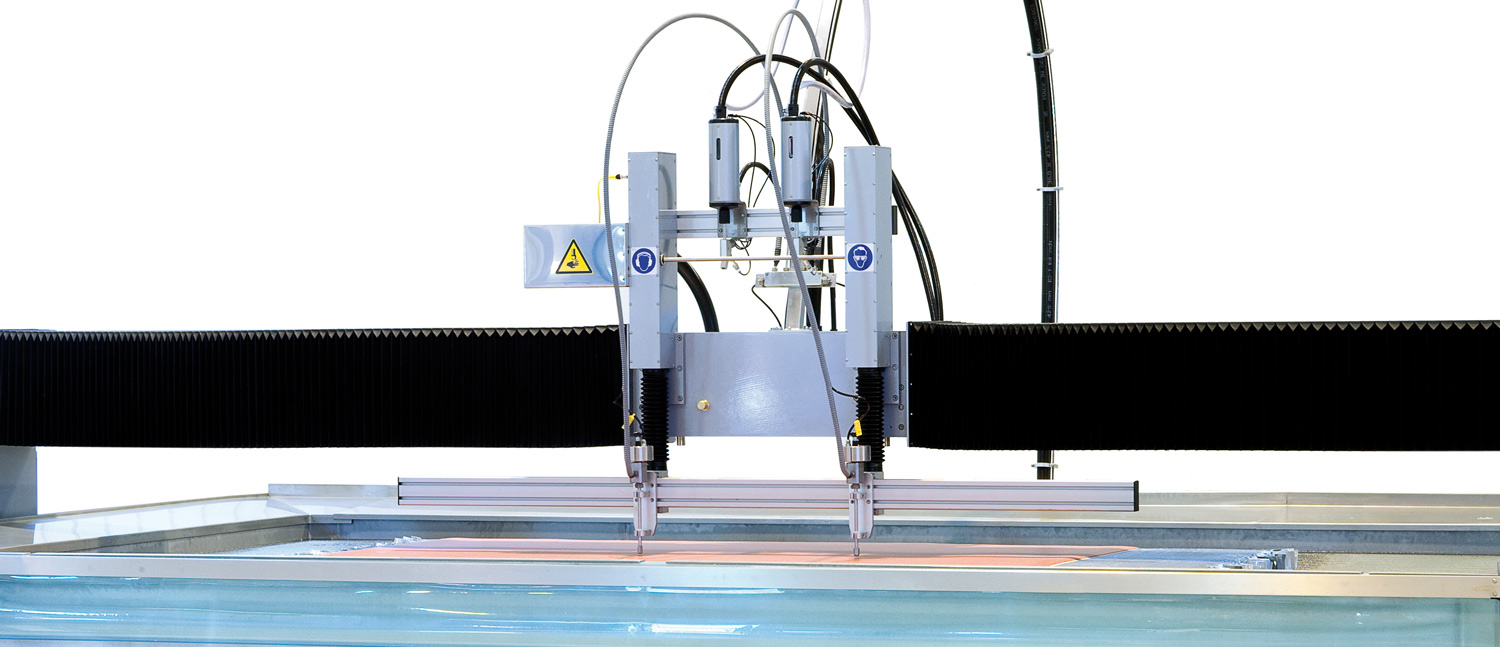

Multi Head Beam

Parallel heads on beam for large-batch production

A solution where the customers benefit stems from the option to easily add more cutting heads to the system as production expands. With a single Z-unit, several cutting heads are mounted on a beam in order to multiply the production capacity. This range is frequently used for both water-only and is also abrasive cutting processes.

Using water jet for production of gaskets and seals allows the economical production of single pieces (e.g. prototypes) with virtually no setup time. When using multiple cutting heads for large-batch production, water jet will often surpass traditional pressing technology. To prevent delamination, some manufacturers utilize an automatic drilling unit alongside the water jet head when piercing laminated gasket materials such as bonded graphite.

Micro Abrasive

Narrow cuts, extreme tolerances and abrasive cutting advantages

The Fine Abrasive Waterjet (FAWJ) process is a refinement of the already proven Abrasive WaterJet (AWJ) process, whereby the advantages are applied to Micro applications.

The biotech sector has been one of the first to adopt the Micro Abrasive model – e.g. for production of implant plates. The technology allows cutting with low material erosion, leaving practically no burr and no heat-effected zones. Thanks to the option to cut thin layers of material, pliant structures can be created. This way, material failure due to structural fatigue can be eliminated.

Pure Water

Soft material and fine incisions

Pure water jet cutting applications (PWJ), on softer materials, use only a high pressure jet stream of water to cut extremely narrow cuts at 0.1 mm. As there is no abrasive required for this process, it is only used for non-metallic materials, foam, rubber and some plastics.

Pure water cutting process is available as standard for all X-series, Premium and Grand models. It is possible to mount up to 16 cutting heads along a common beam, thus multiplying productivity on a single Z-unit.

Product manufacturing

Advanced technology, high value and exacting demands

Our customers within this category represent industries with high quality demands. As manufacturers of technically advanced products (often out of expensive high-tech materials), these customers consider machine performance an important competitive tool.

Common denominators within this category are exacting demands and high goods value: E.g. blanking of titanium plate for aero engines. Cutting Kevlar in composites for personnel and vehicle armor, cutting of thick composite panels for naval patrol boats, shaping of hardened glass and granite for architectural designs or precious metals for jewelry.

Areas as

Aerospace & defence

Transportation & shipping

Automotive

Construction

Fashion & design

Subcontractor

Improved margin by reduced cutting cost per unit

You find a considerable number of WJS customers within this category. They range from highly specialized sub-contractors for specific industry needs to engineering workshops performing a great variety of contract cuttings.

The unique versatility and cutting performance of water jet machines make them keep cost per unit at a minimum. Narrow, precise cuts means efficient nesting and thereby minimum loss of material. The absence of heat-affected zones minimizes the need of second treatment – and with the same tool you can easily cut all shapes, thicknesses and materials.

Areas as

Machine & system engineering

Electronics

Gaskets & seals

Biotech & medical

Power & energy

Public & educational centres

Material processing

Increased process efficiency

The core business within this sector is preparation of raw materials for further processing. Water jet cutting increases total process efficiency by facilitating the next step of production. It yields a smooth cutting surface and narrow cuts – with no heat-affected zones in the cut. When cutting glass, stone & tiles, it also allows very precise crafting of the material. With multiple cutting heads, you can increase productivity considerably.

Areas such as

Metal

Glass

Stone & tiles

Foam, rubber & plastics